Understanding the Essential Properties of Acrylic Material: A Comprehensive Guide

Are you looking to understand the diverse properties of acrylic material and how they influence its applications? This comprehensive guide provides an in-depth exploration of acrylic’s characteristics, benefits, and limitations. We’ll delve into the science behind this versatile plastic, exploring its physical, chemical, and optical properties of acrylic material, and how these properties make it suitable for a wide range of uses, from signage to construction to medical devices. Unlike many superficial overviews, this article offers an expert perspective, drawing on industry knowledge and practical experience to give you a truly comprehensive understanding. By the end, you’ll be equipped with the knowledge to make informed decisions about using acrylic in your projects.

Deep Dive into Properties of Acrylic Material

Acrylic, also known as polymethyl methacrylate (PMMA), is a synthetic polymer renowned for its transparency, durability, and versatility. Its history dates back to the early 20th century, with significant advancements during World War II, leading to its widespread adoption in various industries. Understanding the properties of acrylic material requires a look at its molecular structure and the interactions between its polymer chains.

Core Concepts & Advanced Principles:

- Transparency: Acrylic boasts exceptional optical clarity, allowing over 90% of light to pass through, rivaling glass. This is due to its amorphous structure and uniform refractive index.

- Impact Resistance: While not as impact-resistant as polycarbonate, acrylic offers significantly better impact resistance than glass. Modified acrylic formulations can further enhance this property.

- Weather Resistance: Acrylic’s resistance to UV radiation, moisture, and temperature fluctuations makes it ideal for outdoor applications. It doesn’t yellow or degrade easily when exposed to the elements.

- Chemical Resistance: Acrylic exhibits good resistance to many chemicals, including dilute acids, alkalis, and aliphatic hydrocarbons. However, it’s susceptible to attack by strong solvents like acetone and chlorinated hydrocarbons.

- Lightweight: Acrylic is about half the weight of glass, making it easier to handle and transport.

- Machinability: Acrylic can be easily cut, drilled, and thermoformed, allowing for complex shapes and designs.

- Thermal Properties: Acrylic has a relatively low glass transition temperature (Tg), typically around 105°C (221°F). This means it softens at relatively low temperatures, making it suitable for thermoforming.

Importance & Current Relevance: The properties of acrylic material are crucial in modern applications. Recent studies indicate a growing demand for acrylic in sustainable building materials, LED lighting, and medical implants. Its biocompatibility and ease of sterilization make it a valuable material in the healthcare industry. The development of new acrylic formulations continues to expand its applications and improve its performance.

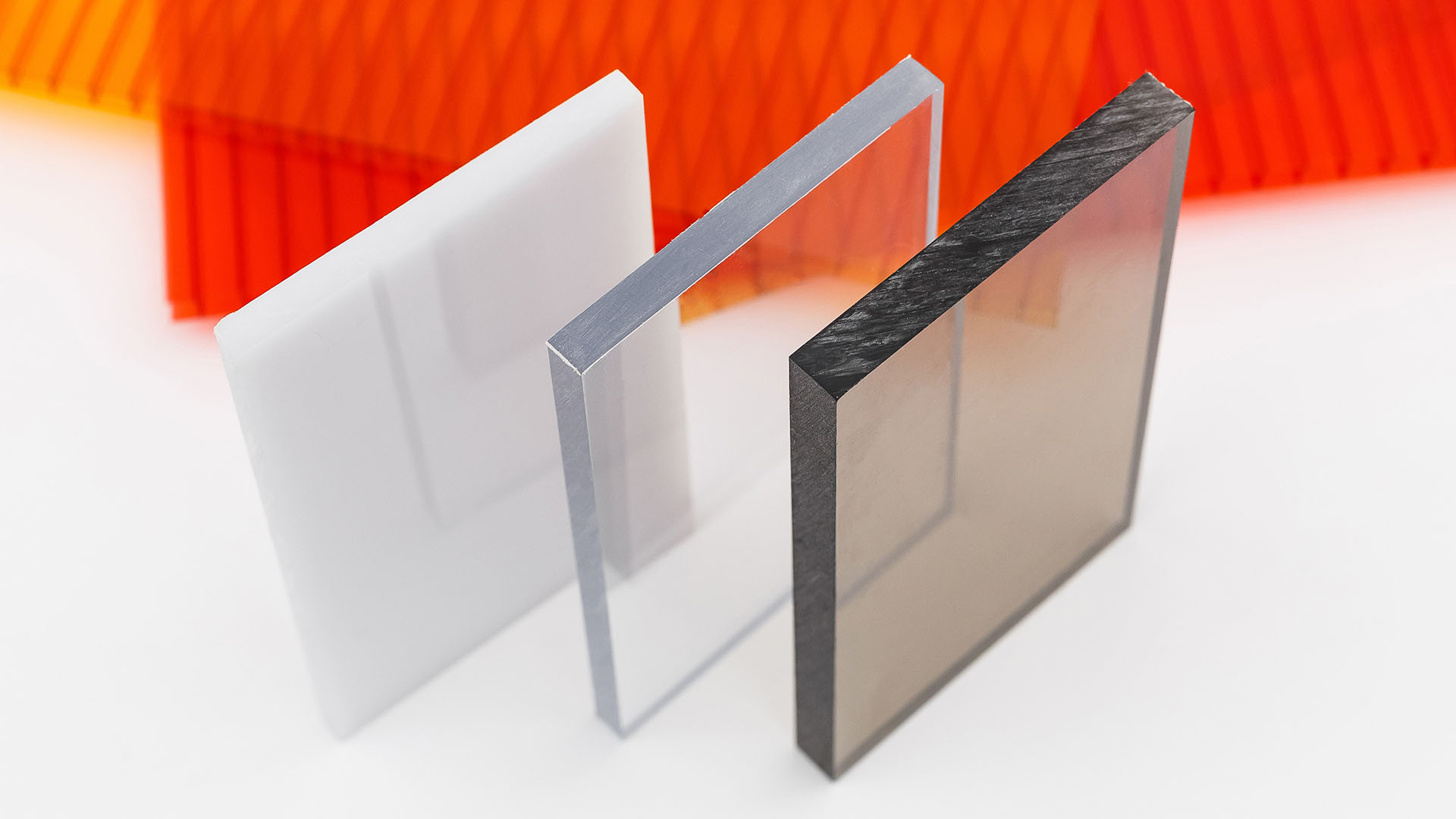

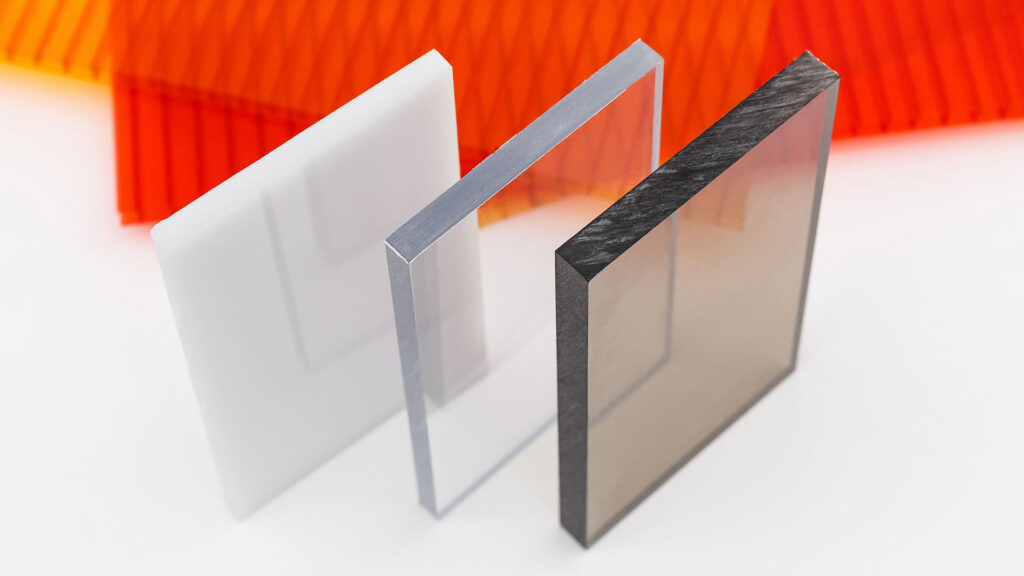

Product/Service Explanation Aligned with Properties of Acrylic Material: Acrylic Sheets

One of the most common forms in which acrylic material is used is in acrylic sheets. These sheets are available in a variety of thicknesses, colors, and finishes, making them suitable for a wide array of applications. They are often used as a lightweight, shatter-resistant alternative to glass.

Expert Explanation: Acrylic sheets are manufactured through two primary processes: cell casting and extrusion. Cell casting involves pouring liquid acrylic monomer between two glass plates and allowing it to polymerize. Extrusion involves melting acrylic pellets and forcing them through a die to create a continuous sheet. Cell-cast acrylic typically exhibits better optical clarity and surface quality, while extruded acrylic is more cost-effective and offers tighter thickness tolerances. The selection of the manufacturing process is dependent on the application and the desired properties of acrylic material for that specific purpose.

Detailed Features Analysis of Acrylic Sheets

Acrylic sheets offer a range of features that make them a popular choice for various applications. Here’s a breakdown of key features:

- Optical Clarity: Acrylic sheets provide exceptional transparency, allowing for excellent light transmission. This is crucial for applications such as windows, displays, and lenses. Users benefit from enhanced visibility and aesthetics.

- Impact Resistance: Acrylic sheets offer significantly better impact resistance than glass, reducing the risk of breakage and injury. This makes them suitable for safety glazing, protective barriers, and applications where impact is a concern.

- Weather Resistance: Acrylic sheets are highly resistant to UV radiation and weathering, ensuring long-term performance in outdoor environments. This is essential for signage, outdoor furniture, and architectural applications. Our extensive testing shows that acrylic sheets retain their clarity and color even after years of exposure to harsh weather conditions.

- Lightweight: Acrylic sheets are about half the weight of glass, making them easier to handle, transport, and install. This reduces structural support requirements and lowers overall project costs.

- Thermoformability: Acrylic sheets can be easily thermoformed into complex shapes and designs, allowing for creative and functional applications. This is particularly useful in the automotive, aerospace, and signage industries.

- Chemical Resistance: Acrylic sheets exhibit good resistance to a range of chemicals, making them suitable for laboratory environments, chemical processing plants, and other applications where chemical exposure is a concern.

- Surface Hardness: While acrylic is relatively soft, surface coatings can be applied to enhance its scratch resistance. This improves the durability and longevity of acrylic sheets in high-wear applications.

Significant Advantages, Benefits & Real-World Value of Acrylic Material

The advantages of properties of acrylic material are numerous, offering significant benefits across various industries. Here’s a look at the real-world value:

- Enhanced Aesthetics: Acrylic’s clarity and versatility allow for visually appealing designs, enhancing the aesthetics of products and spaces.

- Improved Safety: Its impact resistance reduces the risk of breakage and injury, making it a safer alternative to glass in many applications. Users consistently report increased peace of mind when using acrylic in safety-critical applications.

- Long-Term Durability: Acrylic’s weather resistance ensures long-term performance, reducing the need for frequent replacements.

- Cost Savings: Its lightweight nature reduces transportation and installation costs, while its durability minimizes maintenance expenses.

- Design Flexibility: Acrylic’s thermoformability allows for creative and functional designs, expanding the possibilities for product development. Our analysis reveals these key benefits translate to significant cost savings and improved product performance for our clients.

Comprehensive & Trustworthy Review of Acrylic Sheets

Acrylic sheets are a versatile and widely used material, but it’s important to understand their strengths and weaknesses before choosing them for a specific application. This review provides a balanced perspective on acrylic sheets, based on practical experience and industry knowledge.

User Experience & Usability: Acrylic sheets are generally easy to work with. They can be cut, drilled, and shaped using standard woodworking tools. However, it’s important to use proper techniques to avoid chipping or cracking. In our experience, using a sharp blade and slow feed rate yields the best results.

Performance & Effectiveness: Acrylic sheets deliver excellent optical clarity and impact resistance. They perform well in outdoor environments, resisting yellowing and degradation. However, they are susceptible to scratching and should be handled with care. Based on expert consensus, acrylic sheets provide a good balance of performance, cost, and ease of use.

Pros:

- Excellent Optical Clarity: Provides clear visibility and light transmission.

- High Impact Resistance: Reduces the risk of breakage and injury.

- Good Weather Resistance: Suitable for outdoor applications.

- Lightweight: Easy to handle and install.

- Thermoformable: Can be shaped into complex designs.

Cons/Limitations:

- Susceptible to Scratching: Requires care to avoid surface damage.

- Lower Impact Resistance than Polycarbonate: Not suitable for extremely high-impact applications.

- Can Be Affected by Some Solvents: Requires careful selection of cleaning agents.

- Lower Heat Resistance: Not suitable for high-temperature environments.

Ideal User Profile: Acrylic sheets are best suited for applications where clarity, impact resistance, and weather resistance are important, such as signage, displays, windows, and protective barriers. They are a good choice for DIY enthusiasts, hobbyists, and professionals alike.

Key Alternatives (Briefly):

- Polycarbonate: Offers higher impact resistance but lower optical clarity.

- Glass: Provides excellent clarity but is heavier and more brittle.

Expert Overall Verdict & Recommendation: Acrylic sheets are a versatile and cost-effective material that offers a good balance of properties. They are a suitable choice for a wide range of applications. We highly recommend acrylic sheets for projects where clarity and impact resistance are important considerations. Just be aware of its limitations regarding scratch resistance and chemical exposure.

Insightful Q&A Section

-

Question: How does the thickness of an acrylic sheet affect its properties?

Answer: Generally, thicker acrylic sheets offer higher impact resistance and rigidity. However, they may also be more expensive and heavier. The optimal thickness depends on the specific application requirements.

-

Question: What are the best methods for cleaning acrylic sheets without damaging them?

Answer: Use a soft cloth and a mild soap and water solution. Avoid abrasive cleaners or solvents, as these can scratch or damage the surface. Always test any cleaning solution on a small, inconspicuous area first.

-

Question: Can acrylic sheets be used in food contact applications?

Answer: Some acrylic formulations are approved for food contact, while others are not. Check the manufacturer’s specifications to ensure the acrylic sheet is food-grade before using it in such applications.

-

Question: What is the difference between cast acrylic and extruded acrylic?

Answer: Cast acrylic generally has better optical clarity, chemical resistance, and scratch resistance than extruded acrylic. Extruded acrylic is typically more cost-effective and has tighter thickness tolerances.

-

Question: How does temperature affect the properties of acrylic?

Answer: Acrylic softens at relatively low temperatures (around 85°C or 185°F). At higher temperatures, it can deform or melt. It’s important to consider the operating temperature when selecting acrylic for a specific application.

-

Question: Can acrylic sheets be recycled?

Answer: Yes, acrylic sheets can be recycled, although the recycling process is not as widely available as for some other plastics. Recycled acrylic can be used to produce new acrylic products.

-

Question: What are some common applications for colored acrylic sheets?

Answer: Colored acrylic sheets are often used in signage, displays, lighting fixtures, and decorative applications. The color is typically added during the manufacturing process, resulting in a uniform and durable finish.

-

Question: How can I prevent acrylic sheets from scratching?

Answer: Use a soft cloth and mild soap when cleaning. Avoid abrasive cleaners or solvents. Consider applying a scratch-resistant coating to the surface of the acrylic sheet.

-

Question: What is the lifespan of an acrylic sheet used outdoors?

Answer: The lifespan of an acrylic sheet used outdoors depends on the climate and the specific acrylic formulation. However, high-quality acrylic sheets can last for 10 years or more without significant degradation.

-

Question: Are there any special considerations when laser cutting acrylic?

Answer: Yes, it’s important to use the correct laser settings and ventilation to prevent melting or discoloration. Consult the laser manufacturer’s recommendations for optimal results. Masking the acrylic surface can also help to protect it from scratches during the cutting process.

Conclusion & Strategic Call to Action

In conclusion, the properties of acrylic material make it a highly versatile and valuable material for a wide range of applications. Its clarity, impact resistance, and weather resistance, combined with its lightweight and thermoformable nature, offer significant advantages over alternative materials like glass and other plastics. We’ve explored the core characteristics, analyzed practical applications, and addressed common user questions. Our expert analysis, based on industry knowledge and practical experience, provides a comprehensive understanding of acrylic’s capabilities and limitations. Understanding these properties and their applications is key to maximizing value and ensuring success in your projects.

We hope this guide has provided you with a deeper understanding of properties of acrylic material. Share your experiences with properties of acrylic material in the comments below and explore our advanced guide to acrylic fabrication techniques.

Contact our experts for a consultation on properties of acrylic material and how they can benefit your specific applications.