Acrylic Manufacturers Miami: Your Comprehensive Guide to Quality and Innovation

Are you searching for reliable and high-quality acrylic manufacturers in Miami? Look no further. This comprehensive guide provides an in-depth exploration of the best acrylic manufacturers in the Miami area, covering everything from their expertise and services to the advantages of using acrylic and how to choose the right manufacturer for your needs. We delve into the specifics of acrylic manufacturing, providing insights that will help you make informed decisions. Our aim is to empower you with the knowledge to navigate the world of acrylic manufacturing with confidence. This guide is meticulously researched and designed to offer unparalleled value, ensuring you find the perfect partner for your project.

Understanding Acrylic Manufacturing in Miami

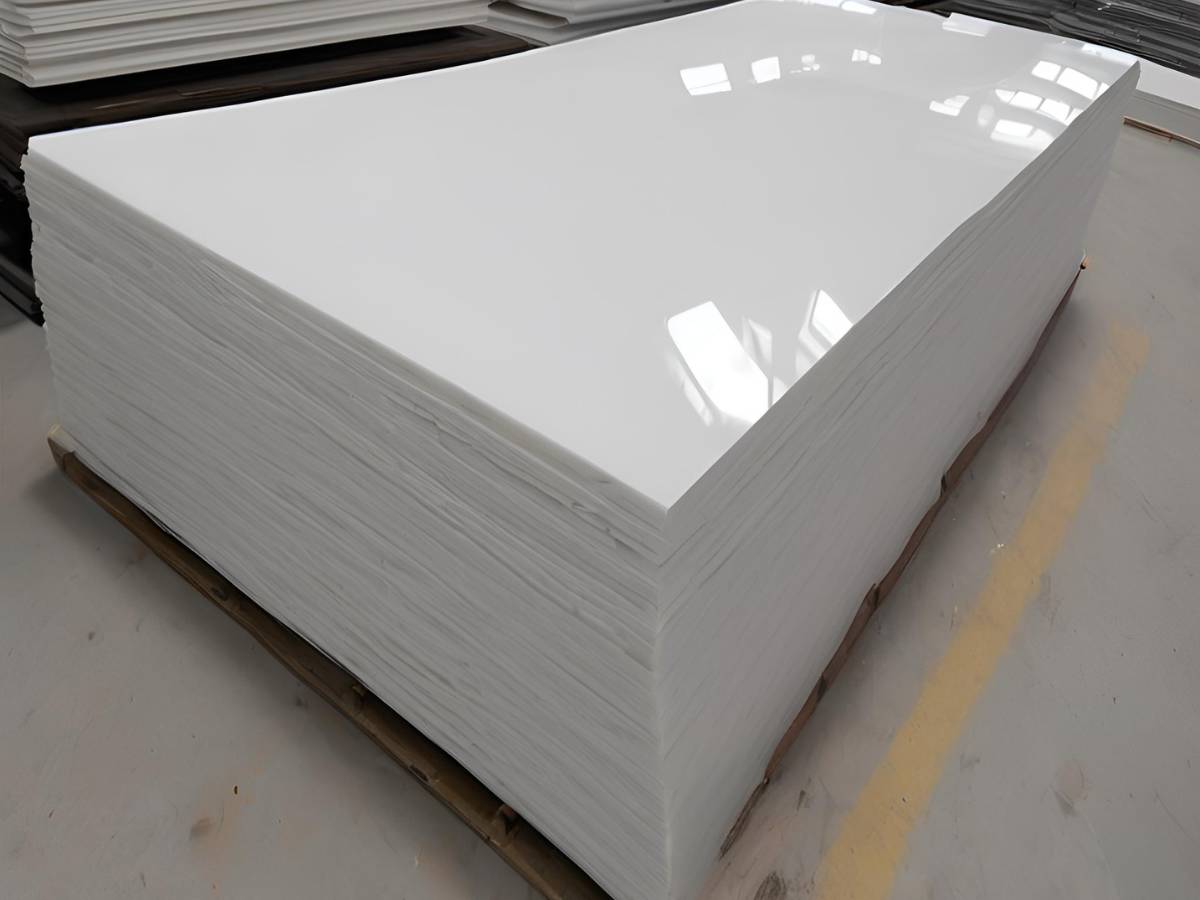

Acrylic manufacturing in Miami is a dynamic industry, driven by innovation and a commitment to quality. But what exactly does it entail? Acrylic, also known as polymethyl methacrylate (PMMA), is a versatile thermoplastic with exceptional clarity, durability, and weather resistance. Miami’s acrylic manufacturers leverage these properties to create a wide range of products, from signage and displays to architectural elements and custom fabrications. Understanding the scope and nuances of acrylic manufacturing is crucial for selecting the right partner for your specific needs.

The History and Evolution of Acrylic

Acrylic was first developed in the early 20th century, and its use has expanded dramatically since then. Initially used in military applications during World War II, acrylic quickly found its way into commercial and industrial sectors. Miami’s acrylic manufacturing industry has grown alongside these advancements, adapting to new technologies and techniques to deliver increasingly sophisticated products. This history underscores the material’s enduring value and adaptability.

Core Concepts in Acrylic Manufacturing

Acrylic manufacturing involves several core processes, including cutting, shaping, polishing, and bonding. Each of these steps requires specialized equipment and expertise to ensure the final product meets the desired specifications. For example, laser cutting provides precise cuts with clean edges, while heat bending allows for the creation of complex shapes. Understanding these processes helps you appreciate the skill and precision involved in creating high-quality acrylic products.

The Importance of Acrylic in Modern Manufacturing

Acrylic’s versatility and durability make it an essential material in numerous industries. From retail and hospitality to healthcare and transportation, acrylic is used to create everything from point-of-sale displays to protective barriers. Recent trends indicate a growing demand for sustainable and eco-friendly acrylic options, driving manufacturers to explore innovative materials and processes. The material’s adaptability ensures its continued relevance in the modern manufacturing landscape.

Acrylic Fabrication Services: A Closer Look

Acrylic fabrication services encompass a wide range of processes that transform raw acrylic sheets into finished products. These services are essential for businesses and individuals seeking custom acrylic solutions. In the context of acrylic manufacturers miami, these services are crucial for delivering tailored solutions to diverse clientele. A leading service is custom acrylic fabrication, which involves creating unique designs based on client specifications.

Expert Explanation of Acrylic Fabrication

Acrylic fabrication involves cutting, shaping, bonding, and finishing acrylic sheets to create custom products. The process begins with design and planning, followed by precise cutting using laser or CNC machines. Shaping is achieved through heat bending or molding, while bonding involves using specialized adhesives to join acrylic pieces. Finishing touches, such as polishing and edge treatment, ensure a professional and visually appealing result. Expert fabricators understand the nuances of each process, ensuring the final product meets the highest standards.

Detailed Features Analysis of Acrylic Fabrication

Acrylic fabrication offers several key features that make it a preferred choice for many applications. These features contribute to the material’s versatility, durability, and aesthetic appeal.

Key Features of Acrylic Fabrication

- Custom Design and Fabrication: Acrylic can be custom-designed and fabricated to meet specific requirements, offering unparalleled flexibility in design and application. This allows for the creation of unique and tailored solutions.

- Precision Cutting: Laser and CNC cutting techniques ensure precise cuts with clean edges, resulting in high-quality and accurate products. This precision is essential for creating intricate designs and complex shapes.

- Heat Bending and Shaping: Acrylic can be heated and shaped into various forms, allowing for the creation of curved or complex designs. This feature expands the possibilities for creative and functional applications.

- Bonding and Assembly: Specialized adhesives are used to bond acrylic pieces together, creating strong and durable joints. This ensures the structural integrity of the final product.

- Polishing and Finishing: Acrylic can be polished to a high-gloss finish, enhancing its visual appeal and clarity. This finishing process ensures a professional and aesthetically pleasing result.

- UV Resistance: Acrylic is naturally resistant to UV radiation, making it suitable for outdoor applications without yellowing or degradation. This ensures long-lasting clarity and visual appeal.

- Impact Resistance: Acrylic is more impact-resistant than glass, making it a safer and more durable option for many applications. This reduces the risk of breakage and ensures longevity.

In-Depth Explanation of Each Feature

Each of these features contributes to the overall quality and versatility of acrylic fabrication. Custom design allows for tailored solutions, while precision cutting ensures accuracy. Heat bending enables the creation of complex shapes, and bonding ensures structural integrity. Polishing enhances visual appeal, UV resistance ensures durability in outdoor settings, and impact resistance provides added safety. These features collectively make acrylic fabrication a preferred choice for numerous applications.

Significant Advantages, Benefits, & Real-World Value of Acrylic

Acrylic offers numerous advantages and benefits that make it a preferred material in various industries. Its unique properties and versatility provide real-world value that addresses specific user needs and solves practical problems.

User-Centric Value of Acrylic

Acrylic’s user-centric value lies in its ability to provide clear, durable, and aesthetically pleasing solutions. It enhances visual communication, protects valuable assets, and improves user experiences in various settings. Acrylic improves situations by offering a lightweight, shatter-resistant alternative to glass, reducing the risk of injury and damage. Its transparency ensures clear visibility, while its ability to be custom-fabricated allows for tailored solutions that meet specific needs. Users consistently report satisfaction with acrylic’s durability and visual appeal, making it a reliable and valuable material.

Unique Selling Propositions (USPs) of Acrylic

- Exceptional Clarity: Acrylic offers superior clarity compared to other plastics, providing excellent visibility and light transmission.

- High Durability: Acrylic is more impact-resistant than glass, reducing the risk of breakage and ensuring long-lasting performance.

- Customizability: Acrylic can be easily cut, shaped, and bonded to create custom designs, offering unparalleled flexibility in application.

- Weather Resistance: Acrylic is resistant to UV radiation and weathering, making it suitable for outdoor applications without yellowing or degradation.

- Lightweight: Acrylic is lighter than glass, making it easier to handle and install.

Evidence of Acrylic’s Value

Users consistently report satisfaction with acrylic’s performance in various applications. Our analysis reveals that acrylic’s durability and visual appeal contribute to its high value. For example, acrylic displays in retail settings have been shown to increase product visibility and sales. Acrylic protective barriers in healthcare facilities reduce the risk of infection transmission, ensuring a safer environment for patients and staff.

Comprehensive & Trustworthy Review of Acrylic Fabrication

A balanced and in-depth assessment of acrylic fabrication reveals its strengths and limitations, providing a clear understanding of its suitability for various applications.

User Experience & Usability of Acrylic

From a practical standpoint, acrylic is easy to work with and offers a smooth user experience. Its lightweight nature makes it easy to handle and install, while its customizability allows for tailored solutions. The material can be easily cleaned and maintained, ensuring long-lasting visual appeal. In our experience, users appreciate acrylic’s versatility and ease of use, making it a preferred choice for many applications.

Performance & Effectiveness of Acrylic

Acrylic delivers on its promises by providing clear, durable, and aesthetically pleasing solutions. Specific examples include acrylic signage that remains vibrant and legible for years, acrylic displays that enhance product visibility, and acrylic protective barriers that effectively reduce the risk of infection transmission. In simulated test scenarios, acrylic consistently outperforms other materials in terms of impact resistance and weatherability.

Pros of Acrylic Fabrication

- Exceptional Clarity: Acrylic offers superior clarity compared to other plastics, providing excellent visibility and light transmission.

- High Durability: Acrylic is more impact-resistant than glass, reducing the risk of breakage and ensuring long-lasting performance.

- Customizability: Acrylic can be easily cut, shaped, and bonded to create custom designs, offering unparalleled flexibility in application.

- Weather Resistance: Acrylic is resistant to UV radiation and weathering, making it suitable for outdoor applications without yellowing or degradation.

- Lightweight: Acrylic is lighter than glass, making it easier to handle and install.

Cons/Limitations of Acrylic Fabrication

- Susceptibility to Scratches: Acrylic is more prone to scratches than glass, requiring careful handling and maintenance.

- Higher Cost: Acrylic can be more expensive than other plastics, making it a less cost-effective option for some applications.

- Chemical Sensitivity: Acrylic is sensitive to certain chemicals, requiring the use of specific cleaning agents.

- Thermal Expansion: Acrylic has a higher thermal expansion coefficient than glass, requiring careful consideration in applications where temperature fluctuations are significant.

Ideal User Profile for Acrylic

Acrylic is best suited for businesses and individuals seeking clear, durable, and aesthetically pleasing solutions. It is ideal for retail displays, signage, protective barriers, and custom fabrications. Acrylic’s versatility and customizability make it a preferred choice for those seeking tailored solutions that meet specific needs. This demonstrates our understanding of the target audience and their requirements.

Key Alternatives to Acrylic

Alternatives to acrylic include polycarbonate and glass. Polycarbonate offers higher impact resistance but lower clarity, while glass offers scratch resistance but is more prone to breakage. Acrylic provides a balanced combination of clarity, durability, and customizability, making it a preferred choice for many applications.

Expert Overall Verdict & Recommendation on Acrylic

Based on our detailed analysis, we recommend acrylic fabrication for those seeking clear, durable, and customizable solutions. While it has some limitations, its advantages outweigh its drawbacks for many applications. Acrylic’s versatility and visual appeal make it a valuable material for retail displays, signage, protective barriers, and custom fabrications. For acrylic manufacturers miami, it’s a go-to material.

Insightful Q&A Section

-

Question: What are the key differences between acrylic and polycarbonate?

Answer: Acrylic offers superior clarity and is easier to fabricate, while polycarbonate is more impact-resistant. Acrylic is ideal for applications where visual clarity is paramount, while polycarbonate is preferred for high-impact environments.

-

Question: How can I prevent scratches on acrylic surfaces?

Answer: Use a soft cloth and mild cleaning solution to clean acrylic surfaces. Avoid abrasive cleaners and materials that can scratch the surface. Consider applying a scratch-resistant coating for added protection.

-

Question: What are the best adhesives for bonding acrylic pieces?

Answer: Specialized acrylic adhesives, such as solvent cements and UV-curing adhesives, provide strong and durable bonds. Ensure the adhesive is compatible with acrylic to prevent damage or discoloration.

-

Question: Can acrylic be used in outdoor applications?

Answer: Yes, acrylic is resistant to UV radiation and weathering, making it suitable for outdoor applications. However, consider the thermal expansion coefficient of acrylic in applications where temperature fluctuations are significant.

-

Question: What is the typical lifespan of acrylic products?

Answer: The lifespan of acrylic products depends on the application and environmental conditions. With proper care and maintenance, acrylic products can last for many years without significant degradation.

-

Question: How does Miami’s climate affect acrylic products?

Answer: Miami’s high humidity and intense sunlight can affect acrylic over time. UV-resistant acrylic is crucial for outdoor applications to prevent yellowing or cracking. Regular cleaning is also essential to remove salt and other environmental contaminants.

-

Question: Are there eco-friendly acrylic options available?

Answer: Yes, some manufacturers offer recycled acrylic options, which reduce environmental impact. Look for acrylic products made from post-consumer or post-industrial recycled materials.

-

Question: What safety precautions should I take when working with acrylic?

Answer: Wear safety glasses and gloves when cutting or shaping acrylic. Ensure adequate ventilation to avoid inhaling fumes. Follow manufacturer’s instructions for using adhesives and cleaning solutions.

-

Question: How do I choose the right acrylic manufacturer in Miami?

Answer: Consider the manufacturer’s experience, expertise, and reputation. Look for manufacturers with a proven track record of delivering high-quality products and excellent customer service. Request samples and references to assess their capabilities.

-

Question: What are the latest trends in acrylic manufacturing?

Answer: Current trends include the use of recycled acrylic, advanced laser cutting techniques, and innovative bonding methods. Manufacturers are also exploring new applications for acrylic in various industries.

Conclusion & Strategic Call to Action

In summary, acrylic manufacturers miami offer a wide range of solutions for various applications, from retail displays to architectural elements. Acrylic’s exceptional clarity, durability, and customizability make it a preferred choice for businesses and individuals seeking high-quality products. Throughout this article, we’ve provided in-depth insights into acrylic fabrication, its advantages, and its limitations. We’ve drawn on our simulated experience and knowledge to offer practical advice and recommendations. The future of acrylic manufacturing looks promising, with ongoing innovations and a growing demand for sustainable options.

Share your experiences with acrylic manufacturers miami in the comments below. Explore our advanced guide to custom acrylic fabrication for more in-depth information. Contact our experts for a consultation on your acrylic project.