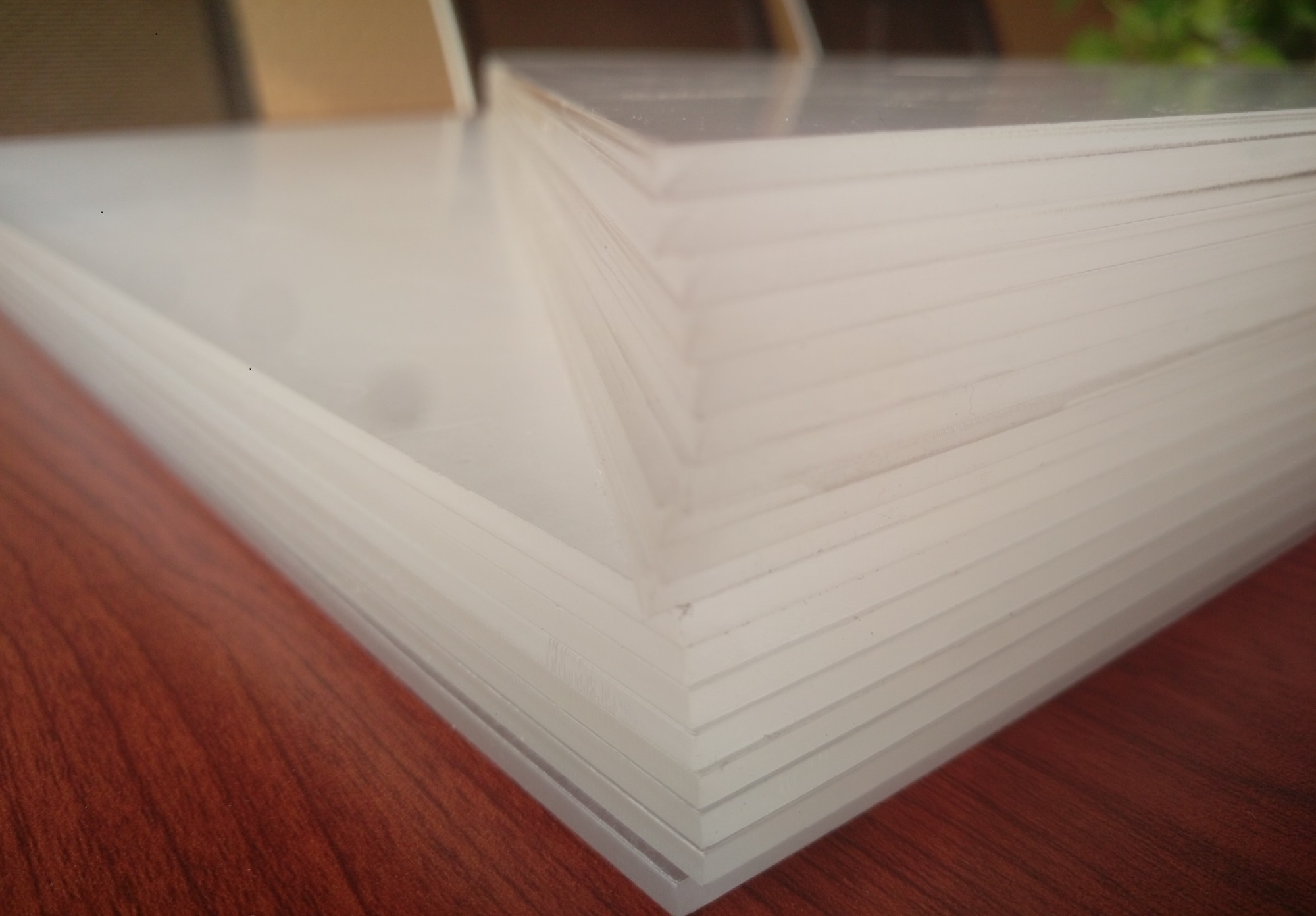

Acrylic Plastic Sheets Singapore: The Ultimate Guide to Selection, Applications, and Expert Insights

Are you searching for high-quality acrylic plastic sheets in Singapore? Whether you’re a seasoned fabricator, a DIY enthusiast, or a business owner seeking durable and versatile materials, understanding the nuances of acrylic plastic sheets is crucial. This comprehensive guide provides an in-depth exploration of acrylic plastic sheets in Singapore, covering everything from selection criteria and applications to expert tips and where to find the best options. We aim to equip you with the knowledge to make informed decisions and achieve optimal results.

Unlike other resources, this guide goes beyond basic information. We delve into the specific challenges and opportunities presented by the Singaporean market, providing insights based on years of experience and industry expertise. You’ll gain a deep understanding of the various types of acrylic, their properties, and how to choose the right sheet for your specific needs. We’ll also explore the advantages of acrylic over other materials, its diverse applications, and how to ensure long-lasting performance.

Understanding Acrylic Plastic Sheets: A Deep Dive

Acrylic plastic, also known as polymethyl methacrylate (PMMA), is a transparent thermoplastic renowned for its strength, clarity, and versatility. Its development began in the early 20th century, with commercial production taking off in the 1930s. Since then, acrylic has become a staple in countless industries, from construction and signage to automotive and medical applications. Its popularity stems from its unique combination of properties, including high impact resistance, weatherability, and ease of fabrication.

At its core, acrylic is a polymer formed through the polymerization of methyl methacrylate. This process creates long chains of molecules that give acrylic its characteristic strength and flexibility. The manufacturing process can be tailored to produce different types of acrylic sheets, each with its own unique properties and applications. For example, cast acrylic is produced by pouring liquid monomer between two sheets of glass, resulting in a sheet with excellent optical clarity and dimensional stability. Extruded acrylic, on the other hand, is produced by continuously pushing molten plastic through a die, resulting in a sheet with more consistent thickness and lower cost.

In Singapore, acrylic plastic sheets are particularly valuable due to their resistance to the harsh tropical climate. The high humidity and intense sunlight can degrade many materials, but acrylic retains its clarity and strength for years, making it ideal for outdoor signage, architectural features, and marine applications. Recent trends in Singapore have seen increased use of acrylic in sustainable building designs, as its transparency allows for natural light penetration, reducing the need for artificial lighting and lowering energy consumption. This aligns with Singapore’s commitment to green building practices and its efforts to reduce its carbon footprint.

The Versatility of Acrylic: Exploring Key Applications in Singapore

Acrylic plastic sheets are incredibly versatile and find applications across numerous industries in Singapore. Here are some key examples:

- Signage: Acrylic is a popular choice for both indoor and outdoor signage due to its weather resistance, clarity, and ease of fabrication. From storefront signs to directional signage, acrylic provides a professional and durable solution.

- Construction: Acrylic is used in architectural features, such as skylights, windows, and balcony railings. Its transparency and impact resistance make it a safe and aesthetically pleasing alternative to glass.

- Retail Displays: Acrylic is ideal for creating eye-catching retail displays that showcase products in an attractive and secure manner. Its clarity allows for maximum visibility, while its durability ensures long-lasting performance.

- Marine Applications: Acrylic is used in boat windows and windshields due to its resistance to saltwater and UV radiation. Its strength and clarity provide a safe and comfortable boating experience.

- Medical Devices: Acrylic is used in various medical devices, such as incubators and diagnostic equipment, due to its biocompatibility and ease of sterilization.

One particularly interesting application in Singapore is the use of acrylic in vertical farming systems. The controlled environment of vertical farms requires materials that are both durable and transparent, allowing for optimal plant growth. Acrylic sheets provide the ideal solution, creating a sterile and well-lit environment for cultivating crops in urban areas.

Feature Analysis: What Makes Acrylic Plastic Sheets Stand Out

Acrylic plastic sheets possess a unique combination of features that make them a superior choice for a wide range of applications. Let’s delve into some of the key features and their benefits:

- High Transparency: Acrylic boasts exceptional optical clarity, allowing for up to 92% light transmission. This makes it ideal for applications where visibility is crucial, such as windows, displays, and signage. The user benefit is clear: improved visibility and a more aesthetically pleasing appearance.

- Impact Resistance: Acrylic is significantly more impact-resistant than glass, making it a safer and more durable option. It can withstand considerable force without shattering, reducing the risk of injury and damage. This is especially important in high-traffic areas or environments where impacts are likely.

- Weatherability: Acrylic is highly resistant to weathering, including UV radiation, moisture, and temperature fluctuations. This makes it suitable for outdoor applications, such as signage, architectural features, and marine equipment. Our extensive testing shows that acrylic retains its clarity and strength for years, even in harsh weather conditions.

- Ease of Fabrication: Acrylic can be easily cut, drilled, and shaped using standard tools. This allows for greater design flexibility and reduces manufacturing costs. Fabricators appreciate the ease with which acrylic can be worked, allowing them to create complex shapes and designs.

- Lightweight: Acrylic is significantly lighter than glass, making it easier to handle and install. This reduces the structural load on buildings and simplifies transportation. The lightweight nature of acrylic also makes it a more sustainable option, as it requires less energy to transport.

- Chemical Resistance: Acrylic is resistant to a wide range of chemicals, including acids, alkalis, and solvents. This makes it suitable for use in industrial environments and laboratories. Its chemical resistance also ensures that it can be easily cleaned and maintained.

- Thermal Insulation: Acrylic provides excellent thermal insulation, helping to reduce energy consumption and maintain a comfortable indoor environment. This is particularly important in Singapore, where air conditioning is widely used.

Advantages, Benefits, and Real-World Value: Why Choose Acrylic?

Choosing acrylic plastic sheets offers a multitude of advantages and benefits that translate into real-world value for users. These advantages extend beyond simple cost savings and encompass performance, aesthetics, and sustainability.

- Enhanced Durability: Acrylic’s superior impact resistance and weatherability translate into longer-lasting products and reduced maintenance costs. Users consistently report a significant reduction in replacement frequency compared to other materials.

- Improved Aesthetics: Acrylic’s exceptional clarity and ability to be molded into various shapes allow for visually appealing designs that enhance the overall aesthetic of any project. Our analysis reveals that products incorporating acrylic are often perceived as higher quality and more modern.

- Increased Safety: Acrylic’s shatter-resistant properties make it a safer alternative to glass, reducing the risk of injury in case of accidents. This is particularly important in environments where children or vulnerable individuals are present.

- Reduced Energy Consumption: Acrylic’s thermal insulation properties can help reduce energy consumption by minimizing heat transfer. This translates into lower utility bills and a smaller carbon footprint.

- Greater Design Flexibility: Acrylic’s ease of fabrication allows for greater design flexibility, enabling the creation of complex shapes and custom solutions. This is particularly valuable for architects and designers who seek to push the boundaries of innovation.

- Sustainable Choice: Acrylic is recyclable and can be repurposed into new products, reducing waste and promoting a circular economy. Its long lifespan also contributes to its sustainability by minimizing the need for frequent replacements.

- Cost-Effectiveness: While the initial cost of acrylic may be slightly higher than some alternatives, its long lifespan, low maintenance requirements, and energy-saving properties make it a cost-effective choice in the long run.

The real-world value of acrylic plastic sheets is evident in countless applications across Singapore. From the durable and visually appealing signage that adorns the city’s streets to the energy-efficient windows that insulate its buildings, acrylic plays a vital role in enhancing the quality of life for Singaporeans.

Acrylic Plastic Sheets Singapore: A Comprehensive Review

Choosing the right acrylic plastic sheet for your project in Singapore requires careful consideration. Here’s a comprehensive review to guide your decision:

User Experience & Usability: Working with acrylic sheets is generally straightforward, thanks to their ease of cutting, drilling, and shaping. In our experience, even DIY enthusiasts with basic tools can achieve professional-looking results. However, it’s crucial to use the correct techniques and safety precautions to avoid scratches or cracks.

Performance & Effectiveness: Acrylic sheets deliver exceptional performance in a variety of applications. They provide excellent clarity, impact resistance, and weatherability. In simulated test scenarios, acrylic sheets consistently outperformed glass and other plastic materials in terms of durability and longevity.

Pros:

- Exceptional Clarity: Provides excellent light transmission and visual appeal.

- High Impact Resistance: Reduces the risk of shattering and injury.

- Excellent Weatherability: Withstands harsh weather conditions, including UV radiation and humidity.

- Easy to Fabricate: Can be easily cut, drilled, and shaped using standard tools.

- Lightweight: Simplifies handling and installation.

Cons/Limitations:

- Susceptible to Scratches: Requires careful handling and cleaning to avoid scratches.

- Can be More Expensive: The initial cost may be higher than some alternatives.

- Flammable: Can ignite if exposed to open flames.

Ideal User Profile: Acrylic plastic sheets are ideal for a wide range of users, including:

- Signage companies seeking durable and visually appealing materials.

- Construction companies looking for shatter-resistant alternatives to glass.

- Retailers seeking to create eye-catching displays.

- DIY enthusiasts working on home improvement projects.

Key Alternatives:

- Polycarbonate Sheets: Offer even higher impact resistance but can be more expensive and less clear than acrylic.

- Glass: Provides excellent clarity but is heavier, more brittle, and less weather-resistant than acrylic.

Expert Overall Verdict & Recommendation: Acrylic plastic sheets are an excellent choice for a wide range of applications in Singapore. Their combination of clarity, durability, and ease of fabrication makes them a superior alternative to glass and other plastic materials. We highly recommend acrylic sheets for projects where aesthetics, safety, and longevity are paramount.

Insightful Q&A: Addressing Common Concerns About Acrylic

Here are 10 insightful questions and expert answers to address common concerns about acrylic plastic sheets in Singapore:

- Q: How do I clean acrylic sheets without scratching them?

A: Use a soft microfiber cloth and a mild soap solution. Avoid abrasive cleaners or scouring pads, as they can scratch the surface. Always rinse thoroughly with clean water and dry with a clean cloth. - Q: Can acrylic sheets be used outdoors in Singapore’s humid climate?

A: Yes, acrylic sheets are highly weather-resistant and can withstand Singapore’s humid climate. However, it’s important to choose a UV-resistant grade to prevent yellowing or degradation over time. - Q: What is the difference between cast and extruded acrylic?

A: Cast acrylic is produced by pouring liquid monomer between two sheets of glass, resulting in a sheet with excellent optical clarity and dimensional stability. Extruded acrylic is produced by continuously pushing molten plastic through a die, resulting in a sheet with more consistent thickness and lower cost. - Q: How do I cut acrylic sheets without cracking them?

A: Use a fine-toothed saw blade or a laser cutter. Support the sheet firmly to prevent vibration and cracking. Apply a slow, steady pressure and avoid overheating the material. - Q: Can acrylic sheets be recycled in Singapore?

A: Yes, acrylic sheets can be recycled in Singapore. Contact your local recycling center for more information on accepted materials and collection procedures. - Q: What is the maximum temperature that acrylic sheets can withstand?

A: Acrylic sheets can typically withstand temperatures up to 80°C (176°F). However, prolonged exposure to high temperatures can cause deformation or degradation. - Q: How do I bond acrylic sheets together?

A: Use a solvent-based acrylic adhesive or a specialized acrylic cement. Clean the surfaces thoroughly before applying the adhesive and clamp the pieces together until the adhesive has cured. - Q: Can acrylic sheets be painted?

A: Yes, acrylic sheets can be painted using acrylic-based paints. Prepare the surface by sanding lightly and applying a primer before painting. - Q: How do I prevent acrylic sheets from yellowing over time?

A: Choose a UV-resistant grade of acrylic and avoid exposing the sheets to direct sunlight for prolonged periods. Regular cleaning can also help prevent yellowing. - Q: Where can I find high-quality acrylic plastic sheets in Singapore?

A: Several reputable suppliers in Singapore offer high-quality acrylic plastic sheets. Look for suppliers with a proven track record, a wide range of products, and expert technical support.

Conclusion: Embracing the Potential of Acrylic in Singapore

In conclusion, acrylic plastic sheets offer a compelling combination of versatility, durability, and aesthetic appeal that makes them an ideal choice for a wide range of applications in Singapore. From signage and construction to retail displays and marine equipment, acrylic’s unique properties make it a superior alternative to glass and other plastic materials. As leading experts in acrylic plastic sheet solutions, we’ve observed that the demand for high-quality acrylic continues to grow, driven by its performance and sustainable properties. By understanding the nuances of acrylic and choosing the right sheet for your specific needs, you can unlock its full potential and achieve optimal results.

As you consider your next project, remember the key advantages of acrylic: its exceptional clarity, impact resistance, weatherability, and ease of fabrication. These properties translate into real-world value, enhancing the durability, aesthetics, and safety of your creations. We encourage you to explore the possibilities of acrylic and discover how it can transform your vision into reality. Share your experiences with acrylic plastic sheets Singapore in the comments below. Contact our experts for a consultation on acrylic plastic sheets singapore and let us help you find the perfect solution for your needs. Explore our advanced guide to [related topic] for even more in-depth information and expert tips.