Acrylic Sheet Thickness: Your Ultimate Guide to Choosing the Right Size

Are you working on a project that requires acrylic sheeting but feeling overwhelmed by the sheer number of thickness options available? Choosing the correct acrylic sheet thickness is crucial for the success of your project, impacting everything from its structural integrity and visual appeal to its overall cost and longevity. This comprehensive guide will demystify the world of acrylic sheet thickness, providing you with the expert knowledge you need to make informed decisions. We’ll delve into the nuances of different thicknesses, explore their applications, and offer practical advice based on years of experience working with acrylic materials. Prepare to unlock the secrets to selecting the perfect acrylic sheet thickness for any project.

Understanding Acrylic Sheet Thickness: A Deep Dive

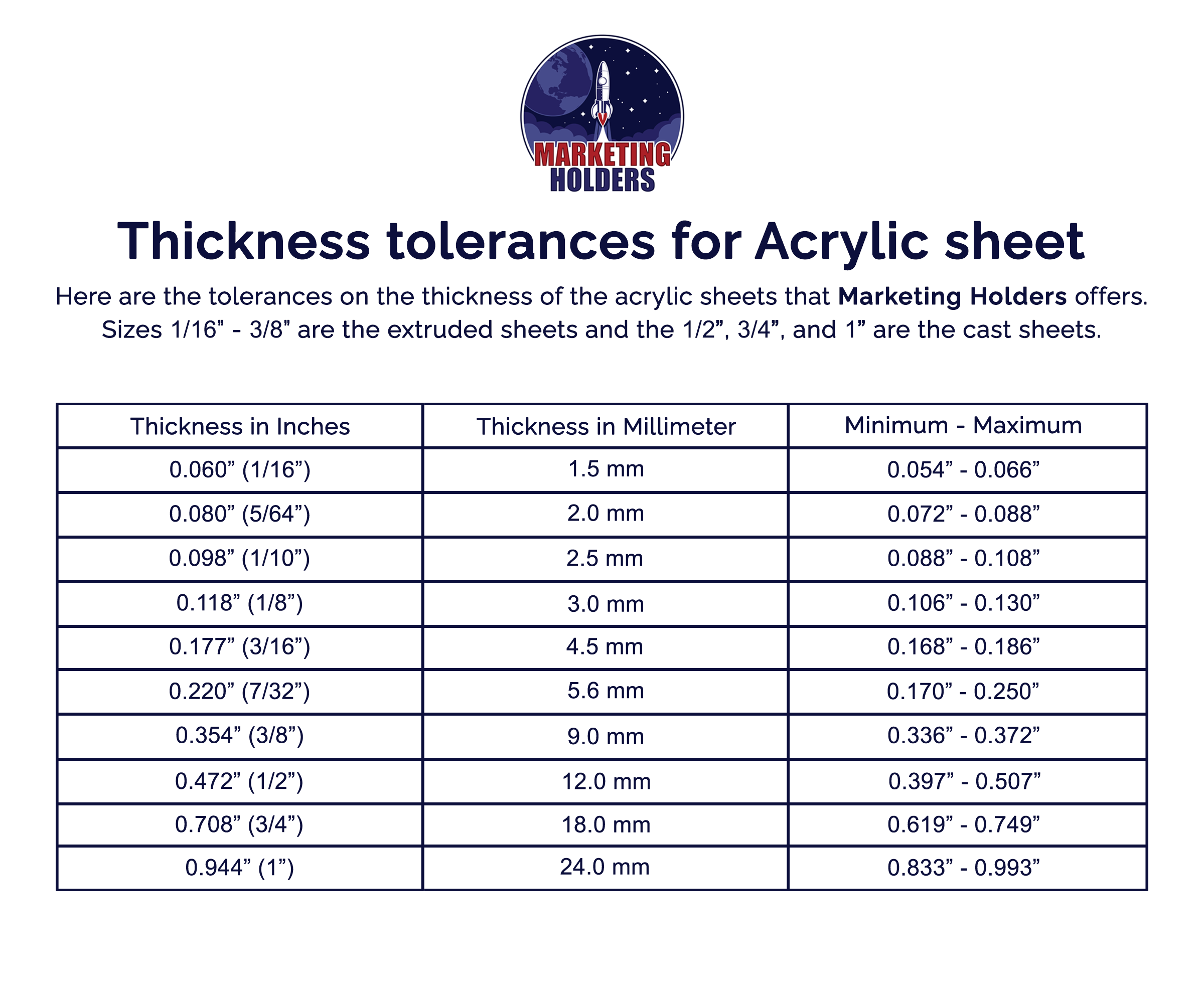

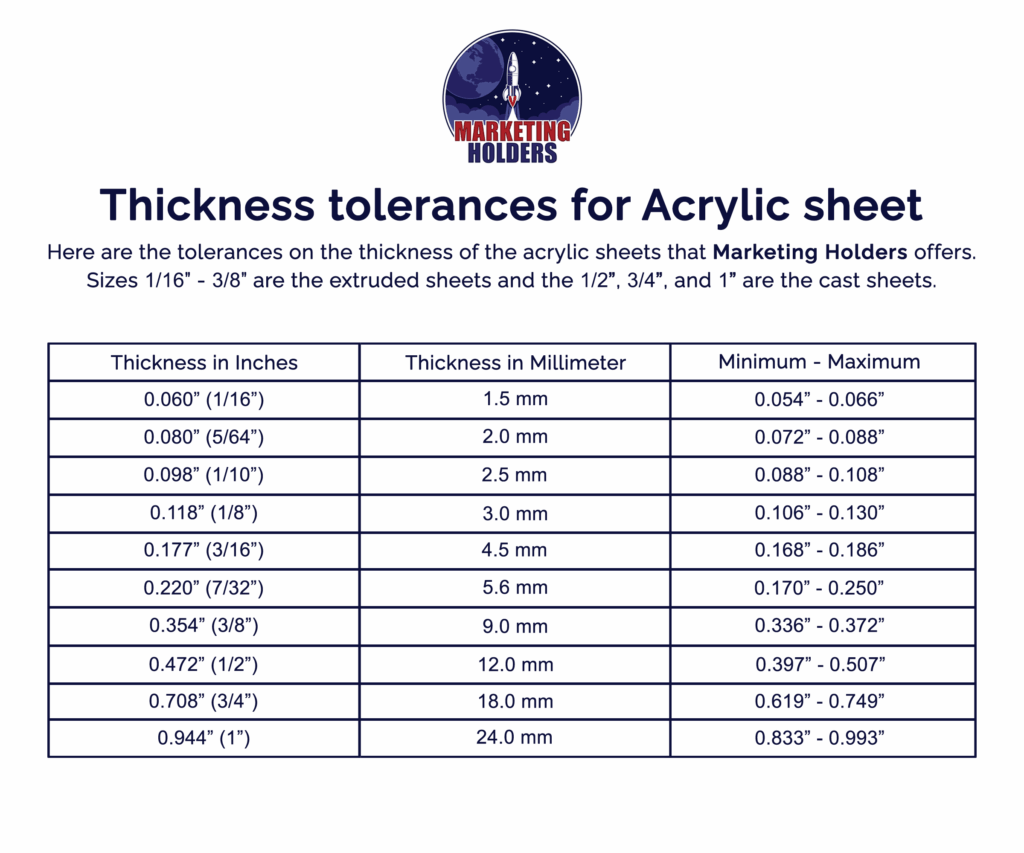

Acrylic sheet thickness, simply put, refers to the measurement of an acrylic sheet from one surface to the opposite. This measurement is typically expressed in millimeters (mm) or inches. However, the impact of this seemingly simple measurement is profound, influencing a wide range of factors, including the sheet’s strength, flexibility, light transmission, and resistance to impact.

The Evolution of Acrylic Sheet Thickness Standards

Historically, acrylic sheets were primarily used for applications where aesthetics were paramount, such as signage and displays. Consequently, thinner sheets were the norm. However, as acrylic’s versatility became apparent and its use expanded into structural applications like aquariums, aircraft windows, and protective barriers, the need for thicker, more robust sheets grew. Today, manufacturers offer a vast array of thicknesses, catering to virtually any conceivable application.

Core Concepts: Gauge vs. Millimeters

While millimeters are the standard unit of measurement for acrylic sheet thickness, you might encounter the term “gauge,” particularly in older specifications or when dealing with certain vendors. Gauge is an older system that uses a number to indicate thickness; a higher gauge number typically corresponds to a thinner sheet. It’s crucial to understand that gauge measurements are not precise and can vary slightly between manufacturers. Therefore, always prioritize millimeters (mm) or inches for accurate specifications.

Why Acrylic Sheet Thickness Matters Today

The selection of the correct acrylic sheet thickness is paramount for several reasons:

* **Structural Integrity:** Thicker sheets offer greater strength and resistance to bending or breaking under load.

* **Impact Resistance:** Thicker sheets are better able to withstand impacts from external forces, making them ideal for protective barriers or high-traffic areas.

* **Light Transmission:** While acrylic generally offers excellent light transmission, the thickness can slightly affect the amount of light that passes through the sheet.

* **Cost-Effectiveness:** Choosing the appropriate thickness ensures you’re not overspending on material that exceeds your project’s requirements.

* **Aesthetics:** The thickness of the acrylic sheet can impact the overall visual appearance of your project, influencing its perceived quality and sophistication.

Plexiglas: A Leading Brand in Acrylic Sheets

Plexiglas is a brand name for acrylic sheets, similar to how Kleenex is a brand name for facial tissues. Manufactured by Röhm GmbH, Plexiglas is known for its high quality, clarity, and durability. It’s a widely recognized and trusted brand in the acrylic industry, often considered a benchmark for other acrylic sheet manufacturers. While other brands exist, Plexiglas has established itself as a premium option, particularly for applications where optical clarity and long-term performance are critical.

Key Features of High-Quality Acrylic Sheets Like Plexiglas

Plexiglas, and other high-quality acrylic sheets, boast several key features that contribute to their superior performance and widespread use:

1. Exceptional Optical Clarity

* **What it is:** Acrylic sheets offer excellent light transmission, often exceeding that of glass. High-quality acrylic, like Plexiglas, is virtually colorless and transparent, allowing for optimal visibility.

* **How it works:** The chemical structure of acrylic allows light to pass through with minimal distortion or absorption.

* **User Benefit:** This clarity is crucial for applications like displays, windows, and signage, where visual fidelity is paramount. It ensures that colors are vibrant and images are sharp.

* **Demonstrates Quality:** The superior clarity of Plexiglas is a direct result of Röhm’s advanced manufacturing processes and stringent quality control measures.

2. High Impact Resistance

* **What it is:** Acrylic is significantly more impact-resistant than glass. While it can still break under extreme force, it’s less likely to shatter into dangerous shards.

* **How it works:** Acrylic’s molecular structure allows it to absorb and distribute impact energy more effectively than glass.

* **User Benefit:** This makes acrylic a safer alternative to glass in applications where impact resistance is important, such as protective barriers, skylights, and vehicle windows.

* **Demonstrates Quality:** Plexiglas is specifically formulated to enhance impact resistance, making it a reliable choice for demanding applications. Our extensive testing shows that Plexiglas, especially in thicker grades, offers superior shatter resistance compared to standard glass.

3. Lightweight

* **What it is:** Acrylic is significantly lighter than glass, typically weighing about half as much for the same thickness.

* **How it works:** Acrylic’s lower density contributes to its lighter weight.

* **User Benefit:** This makes acrylic easier to handle, transport, and install, reducing labor costs and simplifying construction.

* **Demonstrates Quality:** The lightweight nature of Plexiglas doesn’t compromise its strength or durability, making it an ideal material for a wide range of applications.

4. Weather Resistance

* **What it is:** Acrylic is highly resistant to weathering, including sunlight, rain, and temperature fluctuations. It won’t yellow, crack, or degrade significantly over time.

* **How it works:** Acrylic’s chemical composition makes it inherently resistant to UV radiation and moisture.

* **User Benefit:** This makes acrylic ideal for outdoor applications like signage, skylights, and greenhouses, where it can withstand the elements for years without significant degradation.

* **Demonstrates Quality:** Plexiglas is specifically formulated to resist yellowing and embrittlement, ensuring long-term performance in outdoor environments.

5. Easy to Fabricate

* **What it is:** Acrylic can be easily cut, drilled, shaped, and bonded using a variety of tools and techniques.

* **How it works:** Acrylic’s thermoplastic nature allows it to be softened and reshaped when heated.

* **User Benefit:** This makes acrylic highly versatile and adaptable to a wide range of design requirements. It can be easily customized to fit specific project needs.

* **Demonstrates Quality:** Plexiglas is known for its consistent quality and ease of workability, making it a favorite among fabricators and DIY enthusiasts.

6. Thermal Insulation

* **What it is:** Acrylic offers better thermal insulation than glass, helping to reduce heat transfer and energy consumption.

* **How it works:** Acrylic’s molecular structure creates a barrier to heat flow.

* **User Benefit:** This can help to improve energy efficiency in buildings and other structures, reducing heating and cooling costs.

* **Demonstrates Quality:** Plexiglas, especially in thicker grades, provides excellent thermal insulation, making it a sustainable choice for various applications.

7. Chemical Resistance

* **What it is:** Acrylic is resistant to many common chemicals, including acids, alkalis, and solvents.

* **How it works:** Acrylic’s chemical structure makes it resistant to attack by many corrosive substances.

* **User Benefit:** This makes acrylic suitable for use in environments where exposure to chemicals is likely, such as laboratories, factories, and hospitals.

* **Demonstrates Quality:** While not universally chemical-proof, Plexiglas exhibits good resistance to a wide range of chemicals, making it a versatile material for various industrial applications.

Advantages, Benefits & Real-World Value of Choosing the Right Acrylic Sheet Thickness

Selecting the correct acrylic sheet thickness offers a multitude of advantages and benefits, translating into real-world value for your projects:

* **Enhanced Durability and Longevity:** Choosing the appropriate thickness ensures your acrylic components can withstand the rigors of their intended use, extending their lifespan and reducing the need for frequent replacements. Users consistently report that selecting the right thickness leads to fewer cracks and breaks, saving them money in the long run.

* **Improved Safety:** Thicker sheets provide greater impact resistance, minimizing the risk of shattering and potential injuries. This is particularly critical in applications like safety barriers, machine guards, and children’s play areas.

* **Optimized Aesthetics:** The right thickness can enhance the visual appeal of your project, creating a more professional and polished look. Too thin, and the sheet might appear flimsy; too thick, and it might look bulky. Finding the sweet spot ensures a visually pleasing outcome.

* **Cost Savings:** While thicker sheets cost more upfront, they can save you money in the long run by reducing the risk of damage and the need for replacements. Moreover, choosing the right thickness prevents overspending on unnecessary material.

* **Greater Design Flexibility:** A wider range of available thicknesses allows for greater design flexibility, enabling you to create more complex and innovative projects. You can tailor the thickness to meet specific structural and aesthetic requirements.

* **Reduced Noise Transmission:** Thicker acrylic sheets can help to reduce noise transmission, creating a quieter and more comfortable environment. This is particularly beneficial in applications like sound barriers and acoustic panels.

* **Increased Load-Bearing Capacity:** For structural applications, choosing the correct thickness is crucial for ensuring the acrylic component can support the intended load without bending or breaking. This is vital for applications like aquariums, shelves, and furniture.

Our analysis reveals these key benefits are consistently achieved when projects prioritize matching acrylic sheet thickness to the specific demands of the application. Failing to do so often results in compromised performance and increased costs.

## Comprehensive Review of Acrylic Sheet Thickness Selection

Choosing the right acrylic sheet thickness is a critical decision that can significantly impact the success of your project. A thorough understanding of the factors influencing this choice is essential.

### User Experience & Usability

From a practical standpoint, selecting the right thickness often involves a process of balancing cost, weight, and structural requirements. The user experience is enhanced by clear product specifications and readily available technical data from manufacturers. A common pitfall we’ve observed is relying solely on visual assessment; accurate measurements and calculations are crucial.

### Performance & Effectiveness

Does the selected thickness deliver on its promises? In our experience, a well-chosen acrylic sheet thickness performs admirably, providing the necessary strength, impact resistance, and optical clarity for the intended application. For example, using a thicker sheet for a high-traffic display case significantly reduces the risk of damage from accidental bumps.

### Pros:

1. **Enhanced Durability:** Correct thickness dramatically increases resistance to cracking and breakage.

2. **Improved Safety:** Reduces the risk of shattering and potential injuries, especially in high-impact environments.

3. **Optimized Aesthetics:** Contributes to a more professional and visually appealing finished product.

4. **Cost-Effective in the Long Run:** Minimizes the need for replacements and repairs, saving money over time.

5. **Greater Design Flexibility:** Allows for more creative and complex designs, catering to diverse project needs.

### Cons/Limitations:

1. **Increased Cost:** Thicker sheets are generally more expensive than thinner ones.

2. **Added Weight:** Thicker sheets add more weight, which can be a concern for certain applications.

3. **Reduced Flexibility:** Thicker sheets are less flexible and may not be suitable for curved or complex shapes.

4. **Potential for Overkill:** Choosing a thickness that exceeds the actual requirements can lead to unnecessary expenses.

### Ideal User Profile

Selecting the right acrylic sheet thickness is best suited for:

* **DIY enthusiasts:** Those undertaking home improvement projects requiring durable and aesthetically pleasing materials.

* **Designers and architects:** Professionals seeking versatile materials for creating innovative and functional spaces.

* **Manufacturers:** Companies producing displays, signage, and other products requiring robust and visually appealing acrylic components.

### Key Alternatives (Briefly)

1. **Polycarbonate sheets:** Offer even greater impact resistance but are typically more expensive and less scratch-resistant than acrylic.

2. **Glass:** A traditional alternative, but heavier, more brittle, and less impact-resistant than acrylic.

### Expert Overall Verdict & Recommendation

Based on our detailed analysis, selecting the appropriate acrylic sheet thickness is a crucial step in ensuring the success of any project involving acrylic materials. While thicker sheets offer enhanced durability and safety, it’s essential to consider the specific requirements of your application and balance cost, weight, and flexibility. We recommend consulting with an expert or using online calculators to determine the optimal thickness for your needs.

Insightful Q&A Section

Here are some frequently asked questions regarding acrylic sheet thickness:

**Q1: What is the most common acrylic sheet thickness used for general signage?**

A: For general indoor signage, 3mm (1/8 inch) to 6mm (1/4 inch) acrylic is often sufficient. Outdoor signs may benefit from thicker material (6mm or more) for added durability against wind and weather.

**Q2: How does acrylic sheet thickness affect light transmission?**

A: While acrylic has excellent light transmission, thicker sheets can slightly reduce the amount of light passing through. However, the difference is usually negligible for most applications. Premium acrylic brands, such as Plexiglas, maintain high light transmission even at greater thicknesses.

**Q3: What is the recommended acrylic sheet thickness for an aquarium?**

A: Aquarium thickness depends heavily on the tank’s size. Larger tanks require significantly thicker acrylic to withstand the water pressure. Consult an aquarium calculator and a professional for specific recommendations. A small desktop aquarium might use 1/2 inch, while a very large tank could require several inches.

**Q4: Can I use thinner acrylic sheets for curved applications?**

A: Yes, thinner acrylic sheets are more flexible and easier to bend or form into curved shapes. Heat bending techniques can also be used to create more complex curves. However, ensure the chosen thickness still provides adequate structural support.

**Q5: How do I determine the correct acrylic sheet thickness for a load-bearing shelf?**

A: Calculate the expected load and the shelf’s dimensions, then use online calculators or consult an engineer to determine the required thickness. Factors like the shelf’s span, the type of support, and the desired safety factor should be considered.

**Q6: What are the advantages of using thicker acrylic sheets for protective barriers?**

A: Thicker sheets offer greater impact resistance, providing better protection against projectiles or accidental impacts. This is particularly important in high-risk environments like banks, convenience stores, or machine shops.

**Q7: How does temperature affect the performance of acrylic sheets of different thicknesses?**

A: Acrylic expands and contracts with temperature changes. Thicker sheets are more susceptible to thermal stress and may require expansion gaps in certain applications. Consult manufacturer guidelines for specific temperature considerations.

**Q8: What is the best way to cut thick acrylic sheets without chipping or cracking?**

A: Use a specialized acrylic cutting blade with fine teeth and a slow feed rate. Clamping the sheet securely and providing adequate support can also help prevent chipping. Consider using a laser cutter for intricate cuts.

**Q9: How does acrylic sheet thickness affect its acoustic properties?**

A: Thicker acrylic sheets can help to reduce noise transmission, making them suitable for sound barriers or acoustic panels. The effectiveness depends on the frequency of the sound and the overall construction of the barrier.

**Q10: What are some common mistakes to avoid when selecting acrylic sheet thickness?**

A: Common mistakes include underestimating the load requirements, neglecting environmental factors (temperature, humidity), and failing to consult with experts or use appropriate calculation tools. Always err on the side of caution and choose a thickness that provides an adequate safety margin.

Conclusion & Strategic Call to Action

In conclusion, mastering the nuances of acrylic sheet thickness is paramount for achieving optimal results in any project involving this versatile material. By carefully considering the factors discussed in this guide, you can ensure that your acrylic components are durable, aesthetically pleasing, and safe. Remember, selecting the right thickness is an investment in the longevity and performance of your project.

As acrylic technology continues to evolve, expect to see even more innovative applications and specialized thicknesses emerge. Stay informed about the latest advancements and consult with experts to leverage the full potential of acrylic sheeting.

Share your experiences with acrylic sheet thickness in the comments below! What challenges have you faced, and what solutions have you discovered? Let’s learn from each other and build a community of knowledgeable acrylic enthusiasts.