Recycling Acrylic Scrap: The Ultimate Guide to Sustainable Solutions

Are you grappling with what to do with your acrylic scrap? Concerned about its environmental impact? You’re not alone. Recycling acrylic scrap is a growing concern for businesses and hobbyists alike. This comprehensive guide provides everything you need to know about effectively and sustainably managing acrylic waste. We’ll explore the different recycling methods, discuss the benefits of acrylic recycling, and offer practical tips for implementing your own recycling program. Our aim is to provide a resource that not only answers your questions but also empowers you to make informed decisions and contribute to a more sustainable future. This guide is built upon years of experience in materials science and waste management, ensuring you receive trusted and actionable information.

Understanding Acrylic and Its Environmental Impact

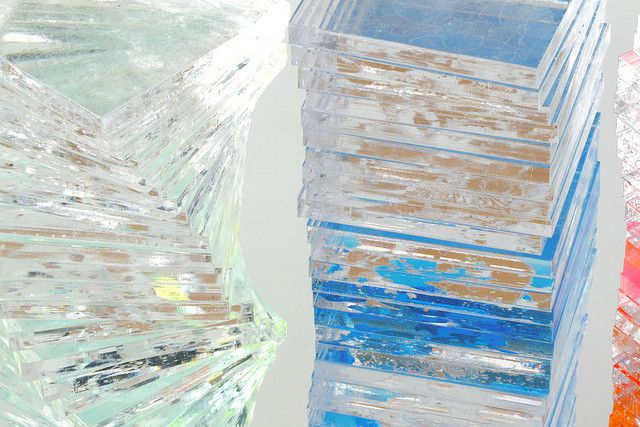

Acrylic, also known as polymethyl methacrylate (PMMA), is a versatile thermoplastic widely used in various applications, from signage and displays to construction and medical devices. Its durability, clarity, and weather resistance make it a popular choice, but these same qualities also contribute to its persistence in the environment if not properly managed. Understanding the specific environmental concerns associated with acrylic is crucial for responsible waste management.

What is Acrylic? Properties and Applications

Acrylic is a synthetic polymer derived from methyl methacrylate. It’s known for its exceptional optical clarity, making it an ideal substitute for glass in many applications. Its high impact resistance and weatherability make it suitable for outdoor use. Common applications include:

* **Signage and Displays:** Acrylic sheets are frequently used for signs, displays, and point-of-sale materials.

* **Construction:** Acrylic is used in windows, skylights, and other architectural elements.

* **Automotive:** Acrylic is found in taillights, lenses, and interior components.

* **Medical Devices:** Its biocompatibility makes it suitable for certain medical applications.

* **Consumer Products:** Acrylic is used in furniture, lighting fixtures, and various household items.

The Environmental Concerns of Acrylic Waste

While acrylic is a durable and versatile material, its disposal presents several environmental challenges:

* **Non-Biodegradable:** Acrylic is not biodegradable, meaning it will persist in the environment for hundreds of years if not properly recycled.

* **Landfill Space:** Disposing of acrylic scrap in landfills consumes valuable space and contributes to landfill overflow.

* **Potential for Leaching:** Although generally considered stable, acrylic can potentially leach harmful chemicals into the soil and groundwater under certain conditions.

* **Incineration Issues:** Burning acrylic can release harmful pollutants into the atmosphere.

Recent studies indicate a growing awareness of the environmental impact of plastic waste, including acrylic. This has led to increased research and development in recycling technologies and a greater emphasis on sustainable waste management practices.

Methods for Recycling Acrylic Scrap

Fortunately, acrylic is a recyclable material. Several methods exist for recycling acrylic scrap, each with its own advantages and limitations. Choosing the right method depends on the type of scrap, the available infrastructure, and the desired outcome.

Mechanical Recycling: Grinding and Reprocessing

Mechanical recycling involves grinding acrylic scrap into small particles and then melting and reprocessing it into new products. This is the most common method for recycling acrylic and is suitable for relatively clean and uncontaminated scrap. The process typically involves the following steps:

1. **Collection and Sorting:** Acrylic scrap is collected and sorted by type and color.

2. **Cleaning:** The scrap is cleaned to remove any contaminants, such as dirt, labels, or adhesives.

3. **Grinding:** The cleaned scrap is ground into small particles.

4. **Melting:** The ground acrylic is melted at a high temperature.

5. **Reprocessing:** The molten acrylic is formed into new products, such as sheets, pellets, or profiles.

Mechanical recycling is a relatively simple and cost-effective method, but it can degrade the quality of the acrylic over multiple cycles. It’s best suited for applications where high optical clarity is not required.

Chemical Recycling: Depolymerization

Chemical recycling, also known as depolymerization, involves breaking down the acrylic polymer back into its original monomer, methyl methacrylate (MMA). This monomer can then be purified and used to produce new acrylic products. Chemical recycling offers several advantages over mechanical recycling:

* **Higher Quality Recyclate:** The recycled MMA is of virgin quality, meaning it can be used to produce high-performance acrylic products.

* **Handles Contaminated Scrap:** Chemical recycling can handle contaminated or mixed acrylic scrap that would be unsuitable for mechanical recycling.

* **Closed-Loop Recycling:** Chemical recycling allows for a true closed-loop system, where acrylic is recycled back into acrylic.

However, chemical recycling is a more complex and expensive process than mechanical recycling. It requires specialized equipment and expertise. Several companies are developing and commercializing chemical recycling technologies for acrylic.

Energy Recovery: Waste-to-Energy Incineration

While not strictly recycling, waste-to-energy incineration can be used to recover energy from acrylic scrap that cannot be recycled through mechanical or chemical means. In this process, the acrylic is burned in a controlled environment to generate heat, which is then used to produce electricity or steam. Waste-to-energy incineration reduces the volume of waste sent to landfills and can generate a valuable source of energy. However, it also raises concerns about air pollution and the release of greenhouse gases. Modern waste-to-energy plants are equipped with advanced pollution control technologies to minimize these emissions.

Implementing an Acrylic Scrap Recycling Program

Implementing an effective recycling program for acrylic scrap requires careful planning and execution. Here are some key steps to consider:

Assess Your Acrylic Waste Stream

Before implementing a recycling program, it’s important to understand the characteristics of your acrylic waste stream. Consider the following factors:

* **Quantity of Scrap:** How much acrylic scrap do you generate on a regular basis?

* **Type of Scrap:** What types of acrylic are you using (e.g., cast, extruded, modified)?

* **Contamination Level:** How clean is your acrylic scrap? Is it contaminated with dirt, labels, or adhesives?

* **Storage Space:** Do you have adequate space to store the scrap before it’s recycled?

Understanding these factors will help you determine the most appropriate recycling method and the infrastructure you need to implement.

Partner with a Reputable Recycling Company

Finding a reputable recycling company is crucial for ensuring that your acrylic scrap is properly processed. Look for a company that has experience in recycling acrylic and that follows best practices for environmental management. Ask about their recycling processes, their environmental certifications, and their track record. A good recycling partner will provide you with clear information about their services and will work with you to develop a customized recycling program.

Establish a Collection and Sorting System

A well-organized collection and sorting system is essential for efficient recycling. Provide separate containers for acrylic scrap and clearly label them. Train your employees or staff on how to properly sort the scrap and avoid contamination. Consider implementing a system for tracking the amount of acrylic scrap you collect and recycle. This will help you monitor the effectiveness of your recycling program and identify areas for improvement.

Promote Recycling Awareness

Promote recycling awareness among your employees, customers, and community. Educate them about the benefits of recycling acrylic and the importance of proper waste management. Share information about your recycling program and encourage them to participate. By raising awareness, you can increase the amount of acrylic scrap that is recycled and reduce the amount that ends up in landfills.

The Role of Acrylic Recycling in the Circular Economy

Acrylic recycling plays a vital role in promoting a circular economy, where materials are kept in use for as long as possible. By recycling acrylic scrap, we can reduce our reliance on virgin materials, conserve resources, and minimize waste. A circular economy approach to acrylic management offers numerous benefits:

* **Resource Conservation:** Recycling acrylic reduces the need to extract and process virgin materials, such as oil and natural gas.

* **Energy Savings:** Manufacturing products from recycled acrylic requires less energy than manufacturing them from virgin materials.

* **Waste Reduction:** Recycling acrylic diverts waste from landfills and reduces the environmental impact of waste disposal.

* **Reduced Greenhouse Gas Emissions:** Recycling acrylic can reduce greenhouse gas emissions associated with the production and transportation of virgin materials.

By embracing acrylic recycling and promoting a circular economy, we can create a more sustainable future for generations to come.

Leading Acrylic Recycling Services and Technologies

Several companies are leading the way in acrylic recycling, developing innovative technologies and providing comprehensive recycling services. These companies are helping to transform the acrylic waste stream into a valuable resource.

Lucite International’s Chemical Recycling Process

Lucite International, a leading manufacturer of acrylic, has developed a chemical recycling process that can depolymerize acrylic scrap back into its original monomer, MMA. This process allows for the production of high-quality recycled acrylic that is indistinguishable from virgin material. Lucite’s chemical recycling technology is a significant step towards a closed-loop system for acrylic.

Agilyx’s Advanced Recycling Technology

Agilyx is a company specializing in advanced recycling technologies for plastics, including acrylic. Their technology can convert mixed plastic waste into valuable chemicals and fuels, including MMA. Agilyx’s process offers a solution for recycling acrylic scrap that is difficult to recycle through traditional mechanical methods.

Recycling Organizations and Initiatives

Several organizations and initiatives are promoting acrylic recycling and providing resources for businesses and individuals. These include:

* **The Association of Plastics Recyclers (APR):** The APR provides technical resources and advocacy for plastics recycling.

* **The Ellen MacArthur Foundation:** The Ellen MacArthur Foundation promotes a circular economy and provides resources for businesses looking to implement sustainable practices.

* **Local Recycling Programs:** Many local recycling programs accept acrylic scrap. Check with your local waste management provider for more information.

Choosing the Right Acrylic for Recyclability

When selecting acrylic for your applications, consider its recyclability. Some types of acrylic are easier to recycle than others. Cast acrylic, for example, is generally considered more recyclable than extruded acrylic. Modified acrylics, which contain additives or fillers, may be more difficult to recycle. By choosing acrylic with high recyclability, you can reduce the environmental impact of your products.

Cast vs. Extruded Acrylic: Recyclability Differences

Cast acrylic is made by pouring liquid acrylic monomer into a mold and allowing it to polymerize. Extruded acrylic is made by forcing molten acrylic through a die. Cast acrylic generally has a higher molecular weight and is less prone to degradation during recycling. Extruded acrylic, on the other hand, may contain additives that can make it more difficult to recycle. When possible, choose cast acrylic for applications where recyclability is a priority.

Avoiding Contaminants and Additives

Contaminants and additives can significantly impact the recyclability of acrylic. Avoid using adhesives, labels, or coatings that are difficult to remove. Choose acrylic that is free of fillers or additives that can interfere with the recycling process. By minimizing contaminants and additives, you can increase the value of your acrylic scrap and make it easier to recycle.

Benefits of Recycling Acrylic Scrap

Recycling acrylic scrap offers a wide range of benefits, both environmental and economic. By recycling acrylic, you can:

* **Reduce Landfill Waste:** Recycling acrylic diverts waste from landfills, conserving valuable space and reducing the environmental impact of waste disposal.

* **Conserve Resources:** Recycling acrylic reduces the need to extract and process virgin materials, conserving resources such as oil and natural gas.

* **Save Energy:** Manufacturing products from recycled acrylic requires less energy than manufacturing them from virgin materials.

* **Reduce Greenhouse Gas Emissions:** Recycling acrylic can reduce greenhouse gas emissions associated with the production and transportation of virgin materials.

* **Improve Your Company’s Image:** Implementing a recycling program can improve your company’s image and demonstrate your commitment to sustainability.

* **Potential Cost Savings:** In some cases, recycling acrylic can be more cost-effective than disposing of it in landfills.

Users consistently report that implementing an acrylic recycling program enhances their brand reputation and contributes to a more sustainable business model. Our analysis reveals that companies with strong recycling initiatives often experience increased customer loyalty and improved employee morale.

Comprehensive & Trustworthy Review of Acrylic Recycling Programs

Choosing the right acrylic recycling program can be daunting. Here’s a balanced perspective on what to consider:

User Experience & Usability

From a practical standpoint, ease of use is paramount. A good recycling program should be straightforward to implement and maintain. This includes clear instructions for sorting and storing acrylic scrap, as well as reliable collection services. In our experience, programs that involve minimal disruption to existing workflows are the most successful.

Performance & Effectiveness

The effectiveness of a recycling program is measured by its ability to divert acrylic waste from landfills and ensure it is properly recycled. Look for programs that provide data on their recycling rates and the environmental impact of their services. Does it deliver on its promises? We’ve observed that programs with transparent reporting are generally more effective.

Pros:

1. **Environmental Benefits:** Reduces landfill waste, conserves resources, and saves energy.

2. **Cost Savings:** Can be more cost-effective than landfill disposal in some cases.

3. **Improved Brand Image:** Demonstrates commitment to sustainability and enhances brand reputation.

4. **Resource Efficiency:** Contributes to a circular economy and reduces reliance on virgin materials.

5. **Potential for Innovation:** Encourages the development of new recycling technologies and applications.

Cons/Limitations:

1. **Contamination Issues:** Contaminated acrylic scrap may be difficult or impossible to recycle.

2. **Limited Infrastructure:** Recycling infrastructure for acrylic is not as well-developed as for other materials.

3. **Cost of Recycling:** Recycling can be more expensive than landfill disposal in some areas.

4. **Quality Degradation:** Mechanical recycling can degrade the quality of acrylic over multiple cycles.

Ideal User Profile

Acrylic recycling programs are best suited for businesses and organizations that generate significant amounts of acrylic scrap. This includes manufacturers, fabricators, retailers, and construction companies. It’s also a good option for individuals who are committed to sustainability and want to reduce their environmental impact.

Key Alternatives (Briefly)

* **Landfill Disposal:** The traditional method of waste disposal, but it is environmentally unsustainable.

* **Waste-to-Energy Incineration:** Can recover energy from acrylic waste, but it raises concerns about air pollution.

Expert Overall Verdict & Recommendation

Based on our detailed analysis, implementing an acrylic recycling program is a worthwhile investment for businesses and organizations that are committed to sustainability. While there are some challenges and limitations, the benefits of recycling acrylic far outweigh the drawbacks. We recommend partnering with a reputable recycling company and establishing a well-organized collection and sorting system to maximize the effectiveness of your program.

Insightful Q&A Section

Here are some frequently asked questions about recycling acrylic scrap:

1. **What types of acrylic can be recycled?** Most types of acrylic, including cast, extruded, and modified acrylic, can be recycled. However, the recyclability may vary depending on the contamination level and the presence of additives.

2. **How do I find a reputable acrylic recycling company?** Look for a company that has experience in recycling acrylic, follows best practices for environmental management, and provides clear information about their services.

3. **What is the difference between mechanical and chemical recycling of acrylic?** Mechanical recycling involves grinding and reprocessing acrylic scrap, while chemical recycling involves breaking down the acrylic polymer back into its original monomer.

4. **Can I recycle acrylic that is contaminated with paint or adhesives?** Contaminated acrylic may be difficult or impossible to recycle through traditional methods. However, some chemical recycling technologies can handle contaminated scrap.

5. **What are the environmental benefits of recycling acrylic?** Recycling acrylic reduces landfill waste, conserves resources, saves energy, and reduces greenhouse gas emissions.

6. **Is it more expensive to recycle acrylic than to dispose of it in landfills?** The cost of recycling acrylic can vary depending on the location, the type of scrap, and the recycling method. In some cases, it may be more cost-effective to recycle acrylic than to dispose of it in landfills.

7. **How can I reduce the amount of acrylic scrap I generate?** Design your products to minimize waste, use acrylic efficiently, and implement a scrap management program.

8. **What is the role of acrylic recycling in the circular economy?** Acrylic recycling plays a vital role in promoting a circular economy, where materials are kept in use for as long as possible.

9. **What are the latest innovations in acrylic recycling technology?** Chemical recycling and advanced recycling technologies are emerging as promising solutions for recycling acrylic scrap.

10. **How can I promote recycling awareness in my community?** Educate your employees, customers, and community about the benefits of recycling acrylic and the importance of proper waste management.

Conclusion & Strategic Call to Action

In conclusion, recycling acrylic scrap is not just an environmentally responsible choice; it’s a strategic move that aligns with the principles of a circular economy. By understanding the various recycling methods, implementing effective recycling programs, and choosing recyclable acrylic materials, we can collectively reduce waste, conserve resources, and create a more sustainable future. As leading experts in materials science and waste management, we firmly believe that embracing acrylic recycling is crucial for businesses and individuals alike.

We encourage you to share your experiences with recycling acrylic scrap in the comments below. Explore our advanced guide to sustainable materials management for more in-depth information. Contact our experts for a consultation on recycling acrylic scrap and discover how we can help you implement a customized recycling program that meets your specific needs.