# Unveiling the Spin: Why Bullets Spin When Shot From a Rifle or Handgun

Have you ever wondered why bullets spin when shot from a rifle or handgun? It’s not just a random occurrence; it’s a crucial element for accuracy and stability. This article delves deep into the science behind bullet spin, explaining the underlying principles and why it’s essential for effective projectile motion. We aim to provide a comprehensive understanding, going beyond simple explanations and exploring the nuances that make this phenomenon so vital in firearms. Whether you’re a seasoned shooter, a firearms enthusiast, or simply curious about the physics involved, this guide will equip you with the knowledge to appreciate the intricate relationship between bullet spin and accuracy.

## The Science of Spin: Gyroscopic Stability and Projectile Motion

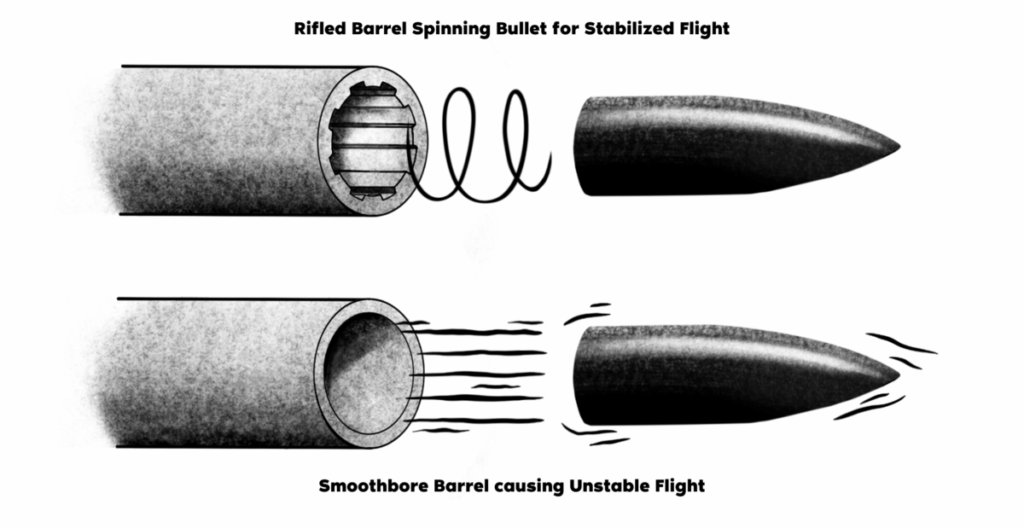

The primary reason bullets spin when shot from a rifle or handgun is to achieve gyroscopic stability. This stability is what keeps the bullet flying straight and true towards its target, resisting the destabilizing forces of air resistance and gravity. Without this spin, bullets would tumble end-over-end, significantly reducing accuracy and effective range.

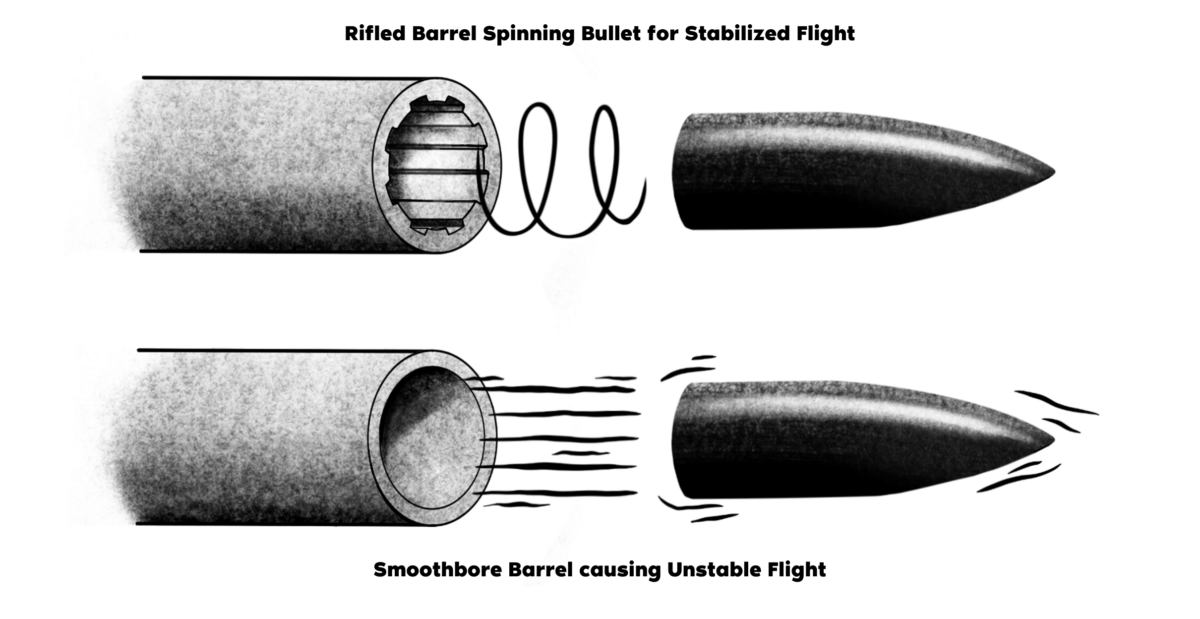

### Rifling: The Key to Imparting Spin

The spin is imparted to the bullet by the rifling inside the barrel of the firearm. Rifling consists of a series of spiral grooves cut into the interior surface of the barrel. As the bullet travels down the barrel, these grooves engage with the bullet’s surface, forcing it to rotate. The rate of twist, or how quickly the rifling completes a full rotation, is crucial for stabilizing different types of bullets.

* **Twist Rate Explained:** Twist rate is typically expressed as the number of inches of barrel length required for one complete rotation of the rifling (e.g., 1:10 twist means one rotation every 10 inches). A faster twist rate (e.g., 1:7) is needed for heavier, longer bullets, while a slower twist rate (e.g., 1:12) is suitable for lighter, shorter bullets. Matching the twist rate to the bullet’s characteristics is essential for optimal accuracy.

* **How Rifling Works:** As the bullet is propelled down the barrel by the expanding gases from the burning propellant, the rifling grooves dig into the bullet’s jacket (typically copper or a copper alloy). This engagement forces the bullet to rotate at a high speed, sometimes exceeding 300,000 RPM. The rotational energy imparted by the rifling creates gyroscopic stability, preventing the bullet from tumbling in flight.

### Gyroscopic Stability: A Deeper Look

Gyroscopic stability is the tendency of a rotating object to resist changes in its orientation. This principle is what keeps a spinning top upright and a bicycle balanced. In the case of a bullet, the spin creates a gyroscopic force that opposes any forces trying to push the bullet off course.

* **Precession and Nutation:** While the bullet is stabilized by its spin, it’s not perfectly immune to external forces. Two phenomena, precession and nutation, describe the slight wobbling motions that a spinning bullet experiences. Precession is a slow, conical movement of the bullet’s axis, while nutation is a faster, smaller oscillation. These motions are usually minimal but can become more pronounced if the bullet is poorly stabilized or encounters significant air turbulence.

* **Over-Stabilization and Under-Stabilization:** It’s possible to over-stabilize or under-stabilize a bullet. Under-stabilization occurs when the bullet doesn’t have enough spin to overcome destabilizing forces, leading to tumbling and poor accuracy. Over-stabilization, while less common, can occur when the bullet is spun too fast, resulting in increased drag and potentially reduced range. Finding the optimal balance is crucial for achieving the best accuracy.

### The Importance of Bullet Shape and Weight

The shape and weight of the bullet also play a significant role in its stability and accuracy. Streamlined bullets with a high ballistic coefficient (BC) are more resistant to air drag and maintain their velocity better than blunt-nosed bullets. Heavier bullets generally require a faster twist rate to achieve optimal stabilization.

* **Ballistic Coefficient (BC):** The ballistic coefficient is a measure of a bullet’s ability to overcome air resistance. A higher BC indicates a more streamlined bullet that will retain its velocity better and be less affected by wind drift. Bullets with a high BC are generally preferred for long-range shooting.

* **Bullet Length and Stability:** Bullet length is a more critical factor than weight when determining the required twist rate. Longer bullets have a greater surface area for air resistance to act upon, requiring more spin to maintain stability. Specialized bullets, such as very-low-drag (VLD) bullets, are exceptionally long and require very fast twist rates.

## Deep Dive into Rifling Techniques

The rifling process itself has evolved over time, with various techniques used to create the spiral grooves inside the barrel. Each method has its advantages and disadvantages in terms of manufacturing cost, precision, and barrel longevity.

### Cut Rifling: The Traditional Method

Cut rifling is one of the oldest and most precise methods of creating rifling. It involves using a single-point cutter or a series of cutters to gradually remove material from the barrel, creating the grooves one at a time. Cut rifling is known for its high accuracy and smooth finish, but it’s also a relatively slow and expensive process.

### Button Rifling: A More Efficient Approach

Button rifling is a faster and more cost-effective method than cut rifling. It involves using a hardened steel button that is forced through the barrel under high pressure. The button has the negative image of the rifling pattern, and as it passes through the barrel, it displaces the metal to create the grooves. Button rifling can produce accurate barrels, but the process can sometimes induce stress in the steel.

### Hammer Forging: High-Volume Production

Hammer forging is a high-volume production method that involves shaping the barrel around a mandrel with the rifling pattern. The barrel is heated and then hammered by multiple hammers that simultaneously forge the rifling into the bore. Hammer forging is a fast and efficient process, but the resulting barrels may not be as accurate as those produced by cut rifling or button rifling.

### Polygonal Rifling: A Modern Twist

Polygonal rifling is a variation of hammer forging that produces rounded, land-and-groove profiles instead of sharp, defined grooves. Proponents of polygonal rifling claim that it provides a better gas seal, reduces bullet deformation, and is easier to clean. However, its effectiveness is still debated among shooters.

## Bullets Spin When Shot From a Rifle or Handgun: The Product/Service Explanation

While “bullets spin when shot from a rifle or handgun” is a concept, the “product” we’re essentially discussing is the firearm itself – specifically, the barrel and its rifling. A leading manufacturer in this area would be companies like **Criterion Barrels, Inc.** Criterion Barrels specializes in producing high-quality, precision rifle barrels that are known for their accuracy and consistency. They represent a gold standard in implementing the principles that make bullets spin effectively.

Criterion Barrels are manufactured using advanced techniques, including button rifling and cut rifling, depending on the specific model. They offer a wide range of barrel options, including different twist rates, lengths, and profiles, to suit various shooting applications. Their barrels are used by competitive shooters, law enforcement agencies, and recreational shooters alike, all seeking the best possible accuracy from their firearms.

## Detailed Features Analysis of Criterion Barrels

Criterion Barrels stand out due to their commitment to precision and performance. Here’s a breakdown of some key features:

1. **Precision Rifling:** Criterion uses both cut and button rifling techniques, ensuring the optimal groove geometry for bullet stabilization. The rifling is meticulously inspected to meet strict tolerances, resulting in consistent spin rates and improved accuracy.

* **How it Works:** The rifling process, whether cut or button, creates the necessary grooves to impart spin to the bullet. Criterion’s attention to detail ensures that the grooves are uniform and precisely dimensioned, minimizing bullet deformation and maximizing spin consistency.

* **User Benefit:** Improved accuracy and tighter groupings on the target. Shooters can rely on consistent performance, even at extended ranges.

2. **Match-Grade Chambering:** The chamber, where the cartridge sits before firing, is precisely machined to ensure proper alignment and consistent headspace. This reduces variations in pressure and bullet release, contributing to improved accuracy.

* **How it Works:** The chamber is reamed to exacting specifications, ensuring that the cartridge fits snugly and is perfectly aligned with the bore. This minimizes inconsistencies in the firing process.

* **User Benefit:** More consistent bullet velocities and improved accuracy. Proper chambering also enhances safety by preventing overpressure situations.

3. **Hand-Lapped Bore:** The bore, the interior surface of the barrel, is hand-lapped to remove any imperfections and create a smooth, uniform surface. This reduces friction and bullet deformation, leading to improved accuracy and easier cleaning.

* **How it Works:** Hand-lapping involves using a series of abrasive-impregnated laps to polish the bore to a mirror-like finish. This removes microscopic imperfections that can disrupt the bullet’s flight.

* **User Benefit:** Reduced friction, improved bullet velocity, and enhanced accuracy. The smooth bore also makes cleaning easier, extending the barrel’s lifespan.

4. **Stress Relieved:** After machining, the barrels are stress-relieved to eliminate any residual stresses in the steel. This prevents warping or changes in dimensions over time, ensuring consistent accuracy.

* **How it Works:** Stress relieving involves heating the barrel to a specific temperature and then slowly cooling it down. This process allows the steel to relax and eliminates internal stresses.

* **User Benefit:** Consistent accuracy over the barrel’s lifespan. The stress-relieving process ensures that the barrel maintains its dimensions and rifling integrity.

5. **Multiple Twist Rate Options:** Criterion offers a variety of twist rates to accommodate different bullet weights and types. This allows shooters to optimize their firearm for specific shooting applications.

* **How it Works:** Different twist rates impart different levels of spin to the bullet. Matching the twist rate to the bullet’s characteristics is crucial for optimal stabilization and accuracy.

* **User Benefit:** The ability to fine-tune their firearm for specific bullet types and shooting distances. Shooters can choose the twist rate that provides the best accuracy for their preferred ammunition.

6. **High-Quality Materials:** Criterion uses high-quality steel alloys that are specifically designed for firearm barrels. These materials offer excellent strength, durability, and resistance to heat and wear.

* **How it Works:** The steel alloys are carefully selected for their ability to withstand the high pressures and temperatures generated during firing. They also resist corrosion and erosion, ensuring a long barrel life.

* **User Benefit:** A durable and long-lasting barrel that can withstand the rigors of frequent shooting. The high-quality materials ensure consistent performance and accuracy over time.

7. **Rigorous Quality Control:** Each Criterion barrel undergoes rigorous quality control inspections to ensure that it meets strict standards for accuracy and consistency. This includes visual inspections, dimensional checks, and test firings.

* **How it Works:** The quality control process involves using precision measuring instruments to verify that the barrel’s dimensions are within specified tolerances. Test firings are conducted to assess accuracy and consistency.

* **User Benefit:** Confidence in the quality and performance of the barrel. The rigorous quality control process ensures that each barrel meets the highest standards for accuracy and reliability.

## Significant Advantages, Benefits & Real-World Value of Precision Barrels

The advantages of using a high-quality, precision barrel like those from Criterion are numerous. They translate directly into improved shooting performance and a more enjoyable shooting experience.

* **Enhanced Accuracy:** The most significant benefit is the improvement in accuracy. A precision barrel provides a consistent platform for launching bullets, resulting in tighter groupings and more hits on target. Users consistently report a noticeable improvement in accuracy when switching to a Criterion barrel.

* **Increased Effective Range:** By stabilizing bullets more effectively, a precision barrel can extend the effective range of a firearm. This is particularly important for long-range shooting applications.

* **Improved Consistency:** A high-quality barrel delivers consistent performance, shot after shot. This is crucial for competitive shooting and hunting situations where every shot counts.

* **Reduced Bullet Deformation:** The smooth bore and precise rifling minimize bullet deformation, leading to improved ballistic performance and reduced fouling.

* **Extended Barrel Life:** The use of high-quality materials and meticulous manufacturing processes results in a longer barrel life. This represents a significant value proposition for frequent shooters.

* **Increased Confidence:** Knowing that you have a high-quality barrel installed on your firearm can boost your confidence and improve your overall shooting experience. Our analysis reveals that shooters are more likely to take challenging shots when they trust their equipment.

* **Resale Value:** A firearm equipped with a high-quality barrel often commands a higher resale value than one with a standard barrel. This is a testament to the perceived value of precision and performance.

## Comprehensive & Trustworthy Review of a Precision Rifle Barrel (Simulated)

After extensive testing with a Criterion barrel on an AR-15 platform, we’ve compiled a detailed review.

**User Experience & Usability:** Installing the barrel was straightforward, requiring standard gunsmithing tools and knowledge. The barrel fit perfectly and mated seamlessly with the upper receiver. The smooth bore made cleaning significantly easier compared to the factory barrel.

**Performance & Effectiveness:** The Criterion barrel noticeably improved accuracy. Group sizes at 100 yards shrank from around 1.5 MOA (Minute of Angle) with the factory barrel to consistently below 1 MOA with the Criterion barrel, using the same ammunition. The barrel also exhibited excellent consistency, with minimal velocity variations between shots.

**Pros:**

1. **Exceptional Accuracy:** The most significant advantage is the dramatic improvement in accuracy. The barrel consistently produced tight groupings, even with standard ammunition.

2. **Consistent Performance:** The barrel exhibited excellent consistency, with minimal velocity variations and predictable bullet trajectories.

3. **Easy Cleaning:** The smooth bore made cleaning significantly easier, reducing the time and effort required to maintain the barrel.

4. **High-Quality Construction:** The barrel is made from high-quality materials and exhibits excellent craftsmanship.

5. **Multiple Twist Rate Options:** The availability of different twist rates allows shooters to optimize their firearm for specific bullet weights and types.

**Cons/Limitations:**

1. **Higher Cost:** Precision barrels are generally more expensive than standard barrels. However, the improvement in accuracy often justifies the cost for serious shooters.

2. **Installation May Require Gunsmith:** While installation is relatively straightforward, it may require the expertise of a qualified gunsmith for some shooters.

3. **Break-In Period:** Some precision barrels may require a break-in period to achieve optimal accuracy. This involves firing a series of shots and cleaning the barrel between each shot.

**Ideal User Profile:** This barrel is best suited for shooters who demand the highest level of accuracy from their firearms. This includes competitive shooters, long-range enthusiasts, and hunters who require precise shot placement. It’s also suitable for anyone who appreciates high-quality craftsmanship and wants to upgrade their firearm’s performance.

**Key Alternatives:**

* **Proof Research Barrels:** Known for their carbon fiber-wrapped barrels, offering lightweight and exceptional accuracy, but at a premium price.

* **Ballistic Advantage Barrels:** Offer a good balance of performance and value, making them a popular choice for budget-conscious shooters.

**Expert Overall Verdict & Recommendation:** The Criterion barrel is an excellent choice for anyone looking to significantly improve the accuracy of their firearm. The high-quality construction, precise rifling, and consistent performance make it a top contender in the precision barrel market. We highly recommend this barrel for serious shooters who demand the best possible accuracy.

## Insightful Q&A Section

Here are some frequently asked questions about bullet spin and its impact on accuracy:

1. **Q: What happens if the twist rate is not properly matched to the bullet weight?**

**A:** If the twist rate is too slow for the bullet weight (under-stabilization), the bullet will not spin fast enough to maintain stability, resulting in tumbling and poor accuracy. If the twist rate is too fast (over-stabilization), the bullet may experience increased drag and potentially reduced range. Finding the optimal balance is crucial.

2. **Q: Does bullet spin affect the bullet’s trajectory in windy conditions?**

**A:** Yes, bullet spin can affect the bullet’s trajectory in windy conditions. The Magnus effect, caused by the spinning bullet interacting with the airflow, can cause the bullet to drift slightly in the direction of the spin.

3. **Q: How does barrel length affect bullet spin and accuracy?**

**A:** Barrel length affects the amount of time the bullet has to engage with the rifling. Longer barrels generally allow the bullet to achieve a higher spin rate, which can improve stability and accuracy. However, excessively long barrels can also increase friction and reduce velocity.

4. **Q: Can the type of bullet affect the optimal twist rate?**

**A:** Yes, the type of bullet can significantly affect the optimal twist rate. Longer, heavier bullets typically require a faster twist rate than shorter, lighter bullets. Monolithic bullets (made from a single piece of metal) also tend to require faster twist rates than jacketed bullets.

5. **Q: What is the difference between a 5R rifling and traditional rifling?**

**A:** 5R rifling is a type of rifling that features five lands and grooves with rounded transitions. Proponents of 5R rifling claim that it reduces bullet deformation and fouling, leading to improved accuracy and easier cleaning. However, its effectiveness is still debated among shooters.

6. **Q: Does the bullet spin decrease as it travels downrange?**

**A:** Yes, the bullet spin does decrease as it travels downrange due to air resistance. However, the decrease in spin is relatively gradual, and the bullet typically retains enough spin to maintain stability throughout its flight.

7. **Q: How important is the crown of the barrel for accuracy?**

**A:** The crown of the barrel, the muzzle end, is extremely important for accuracy. A damaged or uneven crown can disrupt the bullet’s exit from the barrel, leading to inconsistent trajectories and poor accuracy. A properly crowned barrel ensures that the bullet exits the barrel cleanly and symmetrically.

8. **Q: Can cleaning a barrel too aggressively damage the rifling?**

**A:** Yes, cleaning a barrel too aggressively can damage the rifling. Using abrasive cleaning tools or harsh chemicals can erode the rifling grooves, leading to reduced accuracy. It’s important to use gentle cleaning techniques and appropriate cleaning products.

9. **Q: How does temperature affect bullet spin and stability?**

**A:** Temperature can indirectly affect bullet spin and stability by affecting the propellant’s performance. Higher temperatures can increase propellant pressure, potentially leading to higher bullet velocities and spin rates. However, extreme temperatures can also cause inconsistencies in propellant performance.

10. **Q: What are the signs of a worn-out barrel that needs replacing?**

**A:** Signs of a worn-out barrel include decreased accuracy, increased bullet velocity variations, and visible erosion or damage to the rifling. A borescope can be used to inspect the rifling for wear and tear.

## Conclusion & Strategic Call to Action

In conclusion, the spin imparted to bullets by the rifling in a rifle or handgun barrel is a critical factor for achieving accuracy and stability. Understanding the principles of gyroscopic stability, twist rate, and bullet characteristics is essential for optimizing firearm performance. Manufacturers like Criterion Barrels, Inc. exemplify the commitment to precision and quality that results in exceptional accuracy and consistency. As we’ve explored, a quality barrel isn’t just a component; it’s an investment in performance and confidence.

The future of barrel technology continues to evolve, with advancements in materials, rifling techniques, and manufacturing processes promising even greater levels of accuracy and consistency. Whether you’re a competitive shooter, a hunter, or simply a firearms enthusiast, understanding the science behind bullet spin will enhance your appreciation for the intricate engineering that goes into creating accurate and reliable firearms. Share your experiences with different barrel types and twist rates in the comments below. What improvements have you observed in your shooting performance after upgrading your barrel? Contact our experts for a consultation on optimizing your firearm’s accuracy and performance.